NEEDLE VALVE-AS

Needle Valve

Metal Ministry Inc. Needle valves are designed for stringent application in Oil & Gas, Chemical, Petrochemical etc. industries. For application where optimum flow, bi-directional capability or fully roddable design is required, the soft seat gives maximum repeatability, and replacement of seat, if needed, is possible. Standard design has DelrinTM seat and PTFE stem packing. Other seats PEEKTM & KLE-FTM also available on request. These soft seated valves are machined from hexagonal bar stock and are available in sizes 1/4” to 1” in various connections.

FEATURES NEEDLE VALVE-AS

- Valves design provides in-line pipe connections for 1/4” to 1” pipe sizes.

- Rising stem & bar stock body design.

- Stem sleeve and packing gland materials have been carefully chosen to achieve extended thread cycle life and reduced handle torque.

- Available in 316 Stainless Steel, Monel, Duplex & other exotic material.

- Complete material traceability.

- Also available with material compliance to NACE MR-01-75.

- BSPP, BSPT, ISO, Socket & Butt Weld etc. connections available on request.

- Spindle is thread rolled and burnished for smooth operation and long life.

- Temperature range 100°F @ 6000 psi All valves are 100% factory tested with Nitrogen at 70 Bar or Hydro tested at 1.5 times of working pressure.

- Dust and thread caps are provided as standard.

- Threads : N=NPT, G=BSPP, R=BSPT, other option on request.

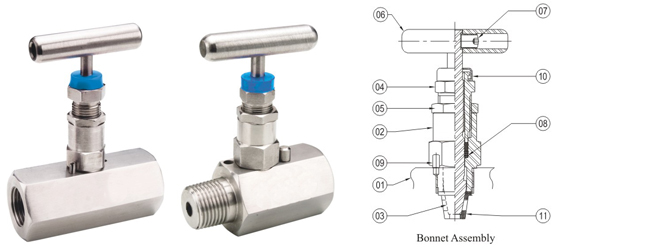

| SOFTEN BONNET ASSEMBLY | |||

| No | Description |

SS 316 valve | C.S. VALVE |

| 1 | Body | SS 316 | C.S. |

| 2 | Bonnet | SS 316 | C.S. |

| 3 | Stem | SS 316 | SS 304 |

| 4 | Adjuster | SS 316 | C.S. |

| 5 | Lock Nut | SS 316 | C.S. |

| 6 | Handle | SS 304 | C.S. |

| 7 | Fixing Screw | C.S. | C.S. |

| 8 | Packing | Teflon | Teflon |

| 9 | Locking Pin | SS304 | S.S. |

| 10 | Dust Cap | Nylon | Nylon |

| 11 | Soft Seat | Delrin | Delrin |