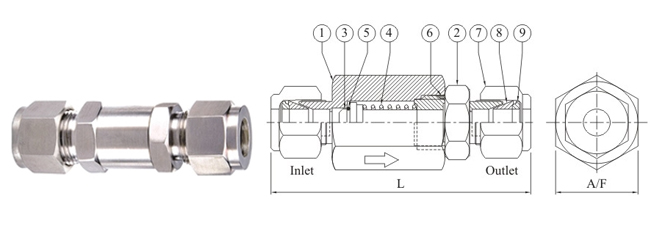

Check Valves

Ball Valve

FEATURES OF CHECK VALVES

- Instant shut off in upstream condition.

- Stops reverse flow in order to protect instrument.

- 100% factory tested for both crack & re-seal.

| Part No | END CONNECTIONS INLET/OUTLET | PRESSURE RATING 100°F (37°C) PSIG |

Dimension MM | Cv | ||

| L | A/F | |||||

| HSCV/TO/02 | FRACTIONAL TUBE FITTING | 1/8" | 6000 | 65 | 16 | 0.23 |

| HSCV/TO/04 | 1/4" | 6000 | 75 | 19 | 0.47 | |

| HSCV/TO/06 | 3/8" | 6000 | 82 | 22 | 1.48 | |

| HSCV/TO/08 | 1/2" | 6000 | 88 | 27 | 1.70 | |

| HSCV/TO/12 | 3/4" | 5000 | 98 | 32 | 5.10 | |

| HSCV/TO/16 | 1" | 4700 | 108 | 38 | 8.12 | |

| HSCV/TO/6M | METRIC TUBE FITTING | 6mm | 6000 | 75 | 19 | 0.47 |

| HSCV/TO/10M | 10mm | 6000 | 82 | 22 | 1.48 | |

| HSCV/TO/12M | 12mm | 6000 | 88 | 27 | 1.70 | |

| HSCV/TO/22M | 22mm | 5000 | 98 | 32 | 5.10 | |

| HSCV/TO/25M | 25mm | 4700 | 108 | 38 | 8.12 | |

| HSCV/MO/02 | MALE NPT x TUBE FITTING | 1/8" | 6000 | 60 | 19 | 0.23 |

| HSCV/MO/04 | 1/4" | 6000 | 68 | 22 | 0.47 | |

| HSCV/MO/06 | 3/8" | 6000 | 70 | 25 | 1.48 | |

| HSCV/MO/08 | 1/2" | 6000 | 82 | 27 | 1.70 | |

| HSCV/MO/12 | 3/4" | 5000 | 85 | 36 | 5.10 | |

| HSCV/MO/16 | 1" | 4700 | 92 | 45 | 8.12 | |

SPECIFICATIONS:

- Max. Working Pressure: up to 6,000 PSI (414 bar), 10,000 PSI on request

- Temperature Ratings: upto 400 F (204 °C)

- Nom. Cracking Pressure: 3, 10, 25 PSI (0.07, 0.69, 1.72 bar)

- Optional cracking pressures up to 100 PSI

- End Connections: Tube

NPT in male and female

ISO taper thread in male and female

DIN and JIC 37°

TYPICAL APPLICATIONS:

- Gas

- Liquid

- Fluid handling for the chemical/petrochemical, research, and oil and gas industries

TYPICAL MATERIALS:

- 316 Stainless Steel

- Other material on request.

Note : Dimensions are reference only and are subject to change.