TECHNICAL TABLES

Just Find Your Technical Answers Below:

| Designation of Diameter | O/D | Nominal Wall Thickness | ||||||||||||||||||

| DIA | SCH.5S | SCH.5 | SCH 10S | SCH.10 | SCH.20S | SCH.30 | SCH.40S | SCH.40 | SCH 60 | |||||||||||

| (A) | (B) | Meter MM |

Wall Thk |

Weight Kg/Mtr | Wall Thk |

Weight Kg/Mtr | Wall Thk |

Weight Kg/Mtr | Wall Thk |

Weight Kg/Mtr | Wall Thk |

Weight Kg/Mtr | Wall Thk |

Weight Kg/Mtr | Wall Thk |

Weight Kg/Mtr | Wall Thk |

Weight Kg/Mtr | Wall Thk |

Weight Kg/Mtr |

| 6 | 1/8 | 10.3 | 1 | 0.23 | 1.2 | 0.27 | 1.5 | 0.33 | 1.73 | 0.37 | ||||||||||

| 8 | 1/4 | 13.7 | 1.2 | 0.37 | 1.65 | 0.49 | 2 | 0.58 | 2.24 | 0.64 | ||||||||||

| 10 | 3/8 | 17.2 | 1.2 | 0.47 | 1.65 | 0.63 | 2 | 0.74 | 2.31 | 0.87 | ||||||||||

| 15 | 1/2 | 21.3 | 1.65 | 0.01 | 1.65 | 0.81 | 2.11 | 1.02 | 2.11 | 1.02 | 2.5 | 1.15 | 2.77 | 1.29 | ||||||

| 20 | 3/4 | 26.7 | 1.65 | 1.03 | 1.65 | 1.03 | 2.11 | 1.3 | 2.11 | 1.3 | 2.5 | 1.49 | 2.87 | 1.71 | ||||||

| 25 | 1 | 33.4 | 1.65 | 1.31 | 1.65 | 1.31 | 2.77 | 2.13 | 2.77 | 2.13 | 3 | 2.24 | 3.38 | 2.54 | ||||||

| 32 | 11/4 | 24.2 | 1.65 | 1.67 | 1.65 | 1.67 | 2.77 | 2.73 | 2.77 | 2.73 | 3 | 2.9 | 3.56 | 3.44 | ||||||

| 40 | 11/2 | 48.3 | 1.65 | 1.93 | 1.65 | 1.93 | 2.77 | 3.16 | 2.77 | 3.16 | 3 | 3.35 | 3.68 | 4.11 | ||||||

| 50 | 2 | 60.3 | 1.65 | 1.93 | 1.65 | 2.42 | 2.77 | 3.99 | 2.77 | 3.99 | 3.5 | 4.9 | 3.91 | 5.52 | ||||||

| 65 | 21/2 | 73 | 2.11 | 3.75 | 2.11 | 3.75 | 3.05 | 5.34 | 3.05 | 5.34 | 3.5 | 6 | 5.16 | 8.77 | ||||||

| 80 | 3 | 88.9 | 2.11 | 4.59 | 2.11 | 4.59 | 3.05 | 6.56 | 3.05 | 6.56 | 4 | 8.37 | 5.49 | 11.47 | ||||||

| 90 | 31/2 | 101.6 | 2.11 | 5.25 | 2.11 | 5.25 | 3.05 | 7.53 | 3.05 | 7.53 | 4 | 9.62 | 5.74 | 13.78 | ||||||

| 100 | 4 | 114.3 | 2.11 | 5.93 | 2.11 | 5.93 | 3.05 | 8.5 | 3.05 | 8.5 | 4.5 | 12.18 | 6.02 | 6.32 | ||||||

| 125 | 5 | 141.3 | 2.77 | 9.61 | 2.77 | 9.61 | 3.4 | 11.74 | 3.43 | 11.74 | 5 | 16.8 | 6.55 | 2210 | ||||||

| 150 | 6 | 168.3 | 2.77 | 11.47 | 2.77 | 11.47 | 3.4 | 14.04 | 3.43 | 14.04 | 5.5 | 22.08 | 7.11 | 28.69 | ||||||

| 200 | 8 | 219.1 | 2.77 | 15 | 2.77 | 15 | 3.76 | 20.77 | 3.76 | 20.27 | 6.35 | 33.82 | 7.04 | 37.38 | 8.18 | 43.2 | 10.81 | 53.9 | ||

| 250 | 10 | 273.1 | 3.4 | 22.95 | 3.4 | 22.95 | 4.19 | 28.2 | 4.19 | 28.2 | 6.35 | 42.41 | 7.8 | 51.81 | 9.27 | 61.22 | 12.2 | 82.8 | ||

| 300 | 12 | 323.9 | 3.96 | 31.72 | 4.19 | 33.6 | 4.57 | 36.54 | 4.57 | 36.54 | 6.35 | 50.48 | 8.38 | 66.2 | 9.53 | 75.01 | 10.31 | 80.94 | 14.27 | 110.62 |

| 350 | 14 | 355.6 | 3.96 | 34.86 | 4.78 | 41.99 | 6.35 | 55.53 | 7.92 | 68.95 | 9.53 | 82.58 | 9.53 | 82.58 | 11.13 | 96 | 15.06 | 128.42 | ||

| 400 | 16 | 406.4 | 4.19 | 42.2 | 4.78 | 48.07 | 6.35 | 63.61 | 7.92 | 79.03 | 9.53 | 94.7 | 9.53 | 94.7 | 12.7 | 125.2 | 16.66 | 162.59 | ||

| 450 | 18 | 457.2 | 4.19 | 47.46 | 4.78 | 54.15 | 6.35 | 71.69 | 7.92 | 89.1 | 11.13 | 124.32 | 9.53 | 106.83 | 14.27 | 158.27 | 19.05 | 209 | ||

| 500 | 2C | 508 | 4.78 | 60.23 | 5.54 | 69.7 | 6.35 | 79.76 | 9.53 | 118.93 | 12.7 | 157.51 | 9.53 | 118.9 | 15.06 | 185.89 | 2062 | 251.65 | ||

| 550 | 22 | 558.8 | 4.78 | 65.95 | 5.54 | 76.75 | 6.35 | 87.84 | 9.53 | 131.07 | 12.7 | 173.66 | 9.53 | 131.07 | 15.88 | 216.04 | 22.23 | 298.55 | ||

| 600 | 24 | 609.6 | 5.54 | 83.8 | 6.35 | 95.92 | 6.35 | 95.92 | 9.53 | 143.2 | 14.27 | 212.72 | 9.53 | 143.2 | 17.45 | 258.74 | 24.59 | 360.21 | ||

| 650 | 26 | 660.4 | 7.92 | 129.4 | 12.7 | 205.97 | 9.53 | 155.32 | ||||||||||||

| 700 | 28 | 711.2 | 7.92 | 139.47 | 12.7 | 222.13 | 15.88 | 276.48 | 9.53 | 167.44 | ||||||||||

| 750 | 3C | 762 | 6.35 | 120.15 | 7.92 | 149.55 | 7.92 | 149.55 | 12.7 | 238.28 | 15.88 | 296.68 | 9.53 | 179.56 | ||||||

| 800 | 32 | 812.8 | 7.92 | 159.62 | 12.7 | 254.44 | 15.88 | 316.88 | 9.53 | 191.69 | 17.48 | 348.11 | ||||||||

| 850 | 34 | 863.6 | 7.92 | 169.64 | 12.7 | 270.5 | 15.88 | 336.96 | 9.53 | 203.74 | 17.48 | 370.22 | ||||||||

| 900 | 36 | 914.4 | 7.92 | 179.77 | 12.7 | 286.75 | 15.88 | 357.28 | 9.53 | 215.93 | 19.05 | 427.09 | ||||||||

| Designation of Diameter | O/D | Nominal Wall Thickness | ||||||||||||||

| DIA | SCH 80 S | SCH 80 | SCH 100 | SCH 120 | SCH. 140 | SCH.160 | SCH.XXS | |||||||||

| (A) | (B) | Meter MM |

Wall Thk |

Weight Kg/Mtr | Wall Thk |

Weight Kg/Mtr | Wall Thk |

Weight Kg/Mtr | Wall Thk |

Weight Kg/Mtr | Wall Thk |

Weight Kg/Mtr | Wall Thk |

Weight Kg/Mtr | Wall Thk |

Weight Kg/Mtr |

| 6 | 1/8 | 10.3 | 2.41 | 0.47 | ||||||||||||

| 8 | 1/4 | 13.7 | 3.02 | 0.82 | ||||||||||||

| 10 | 3/8 | 17.2 | 3.2 | 1.12 | ||||||||||||

| 15 | 1/2 | 21.3 | 3.73 | 1.64 | 4.75 | 1.97 | 7.47 | 2.59 | ||||||||

| 20 | 3/4 | 26.7 | 3.91 | 2.93 | 5.54 | 2.93 | 7.82 | 3.69 | ||||||||

| 25 | 1 | 33.4 | 4.55 | 3.29 | 6.35 | 4.3 | 9.09 | 5.53 | ||||||||

| 32 | 11/4 | 24.2 | 4.85 | 4.53 | 6.35 | 5.69 | 9.7 | 7.88 | ||||||||

| 40 | 11/2 | 48.3 | 5.08 | 5.49 | 7.14 | 7.35 | 10.16 | 9.69 | ||||||||

| 50 | 2 | 60.3 | 5.54 | 7.6 | 8.71 | 11.26 | 11.07 | 13.65 | ||||||||

| 65 | 21/2 | 73 | 7.01 | 11.59 | 9.53 | 15.15 | 14.02 | 20.72 | ||||||||

| 80 | 3 | 88.9 | 7.62 | 15.51 | 11.13 | 21.67 | 15.24 | 28.11 | ||||||||

| 90 | 31/2 | 101.6 | 8.08 | 18.92 | 16.15 | 34.56 | ||||||||||

| 100 | 4 | 114.3 | 8.56 | 22.66 | 11.13 | 28.75 | 13.49 | 34.05 | 17.12 | 41.66 | ||||||

| 125 | 5 | 141.3 | 9.53 | 31.44 | 12.7 | 40.9 | 15.88 | 49.87 | 19.05 | 58.31 | ||||||

| 150 | 6 | 168.3 | 10.97 | 43.21 | 14.27 | 55.03 | 18.24 | 68.53 | 21.95 | 79.1 | ||||||

| 200 | 8 | 219.1 | 12.7 | 65.63 | 15.06 | 76.93 | 18.24 | 91.73 | 20.62 | 102.47 | 23.01 | 112.97 | 22.23 | 108 | ||

| 250 | 10 | 273.1 | 12.7 | 82.8 | 15.06 | 97.27 | 18.24 | 116.38 | 21.41 | 134.9 | 25.4 | 157.51 | 28.58 | 174.95 | 25.4 | 155.5 |

| 300 | 12 | 323.9 | 12.7 | 98.95 | 17.45 | 133.88 | 21.41 | 162.14 | 25.4 | 189.82 | 28.58 | 211.31 | 33.32 | 242.4 | 25.4 | 189.82 |

| 350 | 14 | 355.6 | 12.7 | 109.04 | 19.05 | 160.54 | 23.8 | 197.74 | 27.76 | 227.88 | 31.75 | 257.47 | 35.71 | 286.04 | ||

| 400 | 16 | 406.4 | 12.7 | 125.2 | 21.41 | 206.4 | 26.19 | 249.34 | 30.94 | 290.88 | 36.53 | 338.32 | 40.46 | 370.74 | ||

| 450 | 18 | 457.2 | 12.7 | 141.35 | 23.8 | 258.29 | 29.36 | 314.54 | 34.93 | 369.34 | 39.67 | 414.74 | 45.24 | 466.67 | ||

| 500 | 2C | 508 | 12.7 | 157.51 | 26.19 | 315.97 | 32.54 | 387.41 | 38.1 | 448.3 | 44.45 | 515.94 | 49.99 | 573.31 | ||

| 550 | 22 | 558.8 | 12.7 | 173.66 | 28.57 | 379.7 | 34.92 | 457.83 | 41.27 | 535.17 | 47.62 | 609.3 | 53.97 | 682.57 | ||

| 600 | 24 | 609.6 | 12.7 | 189.82 | 30.94 | 448.3 | 38.89 | 555.76 | 46.02 | 649.44 | 52.37 | 730.72 | 59.51 | 819.7 | ||

| 650 | 26 | 660.4 | 12.7 | 205.97 | (24.66D-t) t 1000 Wt/pam + formula Weight Stainless Steel Pipe OD (mm) - W.T. (mm) XW.T. (mm) X 0.02466 = Kg. per mtr. |

|||||||||||

| 700 | 28 | 711.2 | 12.7 | 222.13 | ||||||||||||

| 750 | 3C | 762 | 1270 | 238.28 | ||||||||||||

| 800 | 32 | 812.8 | 12.7 | 254.44 | ||||||||||||

| 850 | 34 | 863.6 | 12.7 | 270.5 | ||||||||||||

| 900 | 36 | 914.4 | 12.7 | 286.75 | ||||||||||||

| Dimension | 10SWg | 12SWg | 14SWg | 16SWg | 18SWg | 20SWg | 22SWg | |

| Size inches | OD in mm | 3.25mm Wt Kg/M | 2.64mm Wt Kg/M | 2.03mm Wt Kg/M | 1.62mm Wt Kg/M | 1.21mm Wt Kg/M | 0.91mm Wt Kg/M | 0.71mm Wt Kg/M |

| 3/8 | 9.52 | 0.549 | 0.447 | 0.405 | 0.341 | 0.268 | 0.193 | 0.165 |

| 1/2 | 12.7 | 0.768 | 0.654 | 0.542 | 0.451 | 0.350 | 0.264 | 0.213 |

| 3/4 | 19.05 | 1.285 | 1.068 | 0.864 | 0.710 | 0.544 | 0.407 | 0.320 |

| 1 | 25.4 | 1.801 | 1.482 | 1.187 | 0.969 | 0.738 | 0.549 | 0.432 |

| 1 1/4 | 31.75 | 2.801 | 1.482 | 1.187 | 0.969 | 0.738 | 0.549 | 0.432 |

| 1 1/2 | 38.1 | 2.834 | 2.309 | 1.832 | 1.487 | 1.126 | 0.820 | 0.654 |

| 1 3/4 | 45.00 | 3.408 | 2.722 | 2.191 | 1.775 | 1.341 | 0.834 | |

| 2 | 50.8 | 3.868 | 3.136 | 2.478 | 2.006 | 1.541 | 1.119 | 0.877 |

| 2 | 50.8 | 3.868 | 3.136 | 2.478 | 2.006 | 1.541 | 1-119 | 0.877 |

| 2 1/2 | 63.5 | 4.901 | 3.963 | 3.123 | 2.524 | 1.858 | - | - |

| 3 | 76.2 | 5.934 | 4.790 | 3.453 | 2.789 | 2.237 | - | - |

| 3 1/2 | 88.9 | 6.964 | 5.617 | 4.413 | 3.560 | 2.616 | - | - |

| 4 | 101.6 | 8.000 | 6.444 | 5.059 | 4.078 | 2.995 | - | - |

| 4 1/2 | 114.3 | 8.900 | 7.272 | 5.620 | 4.501 | 3.374 | - | - |

| 5 | 127-0 | 9.917 | 8.099 | 6.255 | 5.008 | 3.753 | - | - |

| 6 | 152.4 | 11.953 | 9.753 | 7.527 | 6.023 | 4.474 | - | - |

| Specification | Allowable Outside Diameter Variation in mm | Allowable Wall Thickness Variation | Exact Length Tolerance in mm | Testing | ||||

| Nominal Diameter | Over | Under | %Over | %Under | Over | Under | ||

| ASTM-A213 Seamless Boiler Superheater and Heat Exchanger Tubes |

Under 25.4 | .1016 | .1016 | +20 | -0 | 3.175 | 0 | Flattening Test |

| 25.4-38.1 incl | .1524 | .1524 | +22 | -0 | 3.175 | 0 | Tension Test | |

| 38.1-50.8 excl | .2032 | .2032 | +22 | -0 | 3.176 | 0 | Flare Test | |

| 50.8-63.5 excl | .254 | .254 | +2 | -0 | 4.46 | 0 | Hardness Test | |

| 63.5-76.2 excl | .3048 | .3048 | +22 | -0 | 4.76 | 0 | 100% Hydrostatic test | |

| 76.2-101.6 incl | .381 | .381 | +22 | -0 | 4.76 | 0 | Refer to ASTM A-450 | |

| ASTM-A249 Welded Boiler Superheater, Heat Exchanger And Condenser Tubes |

Under 25.4 | .1016 | .1016 | +10 | -10 | 3.175 | 0 | Tension Test |

| 25.4-38.1 incl | .1524 | .1524 | +10 | -10 | 3.175 | 0 | Flattening Test | |

| 38.1-50.8 Excl | .2032 | .2032 | +10 | -10 | 3.175 | 0 | Flange Test | |

| 50.0-63.5 excl | .254 | .254 | +10 | -10 | 4.762 | 0 | Reverse Bend Test | |

| 63.5-76.2 excl | .3848 | .3848 | +10 | -10 | 4.762 | 0 | Hardness Test | |

| 76.2-101.6 incl | .381 | .381 | +10 | -10 | 4.762 | 0 | 100% Hydrostastic Test Refer to ASTM A-450 | |

| Minimum Wall tubes +18% 0 available On request | ||||||||

| ASTM-A269 Seamless & Welded Tubing for General Service |

Untp12.7 | .13 | .13 | +15 | -15 | 3.2 | 0 | Flare Test (Seamless Only) |

| 12.7-38.1 exc! | .13 | .13 | +10 | -10 | 3.2 | 0 | Flange Test (Welded Only) | |

| 38.1-88.9 excl | .25 | .25 | +10 | -10 | 4.8 | 0 | Hardness Test | |

| 88.9-139.7 excl | .38 | .38 | +10 | -10 | 4.8 | 0 | Reverse Flattening Test | |

| 139.7-203.2 excl | .76 | .76 | +10 | -10 | 4.8 | 0 | (Welded only) 100% Hydrostatic Test Refer to ASTM-A269 |

|

| ASTM-A270 Seamless & Welded Sanitary Tubing |

25.4 | .05 | .20 | +10.0 | -10.0 | 3.2 | 0 | Reverse flattening Test |

| 38.1 | .05 | .20 | +10.0 | -10.0 | 3.2 | 0 | 100% Hydrostastic Test | |

| 50.8 | .05 | .28 | +10.0 | -10.0 | 3.2 | 0 | External' polish on all tubes | |

| 60.5 | .05 | .28 | +10.0 | -10.0 | 3.2 | 0 | Refer to ASTM A-270 | |

| 76.2 | .08 | .30 | +10.0 | -10.0 | 3.2 | 0 | ||

| 101.6 | .08 | .38 | +10.0 | -10.0 | 3.2 | 0 | ||

| ASTM-A312 Seemless & Welded pipe |

3.175-38.1 incl | .4 | .79 | Minimum Wall 12.5% under nominal wall Specified | 6.4 0 | 0 | Tension Test | |

| 38.1-1016 incl | .79 | .79 | 6.4 0 | 0 | Flattening Test | |||

| 101.6-203.2 imcl | 1.59 | .79 | 6.4 0 | 0 | 100% Hydrostatic Test | |||

| (Normally Random Lengths ordered | Refer to ASTM A-530 | |||||||

| ASTM A-358 Welded pipe |

219.08-750mm or 0.01 inch | +0.5% | -0.3 | 6.0 | Refer to ASTM A-530 | |||

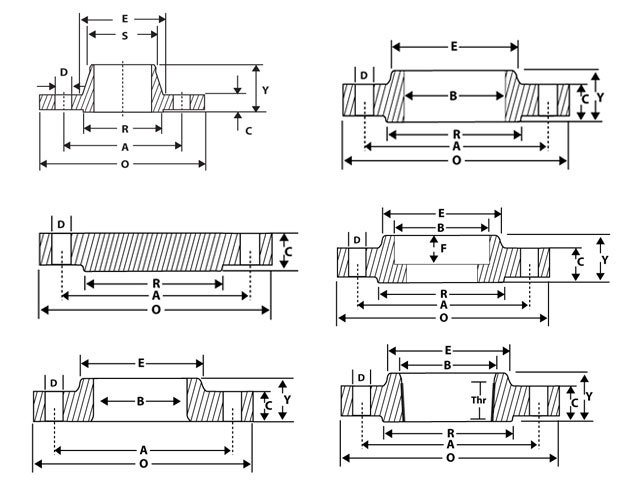

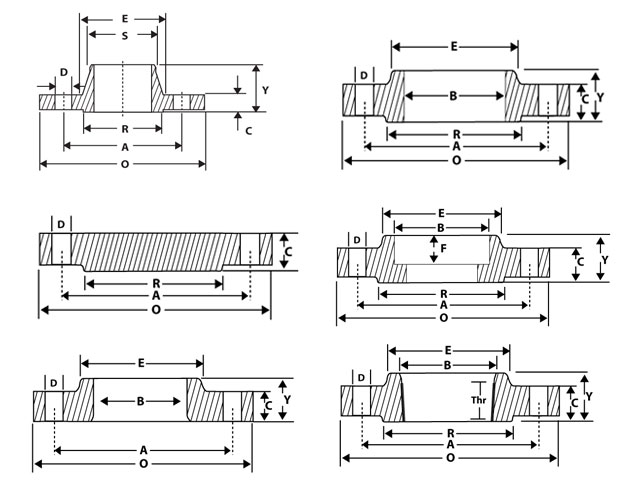

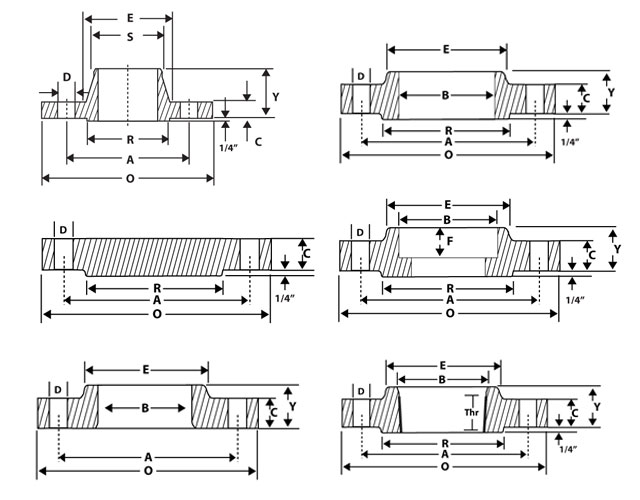

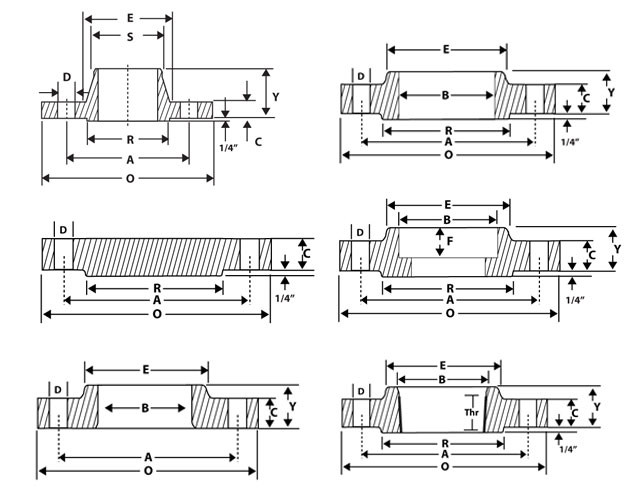

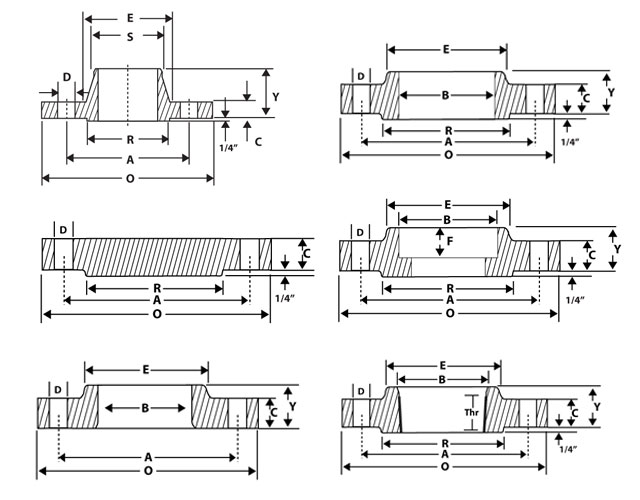

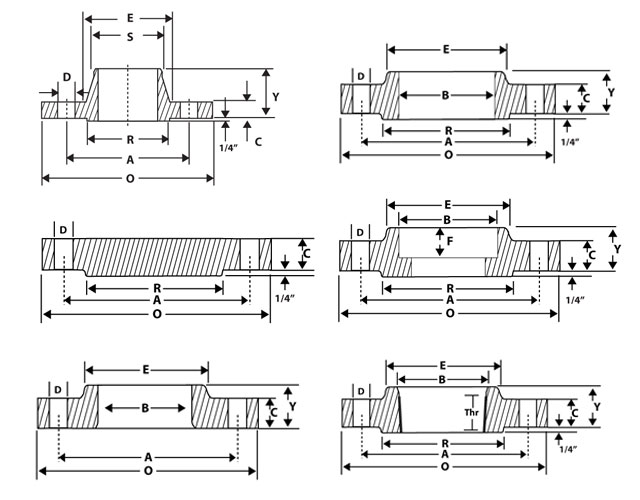

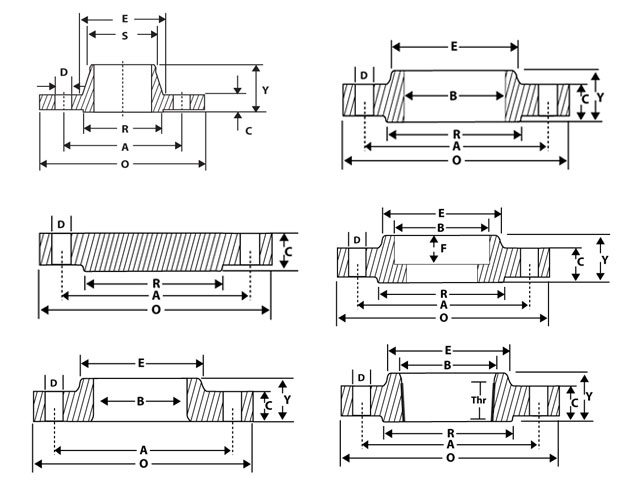

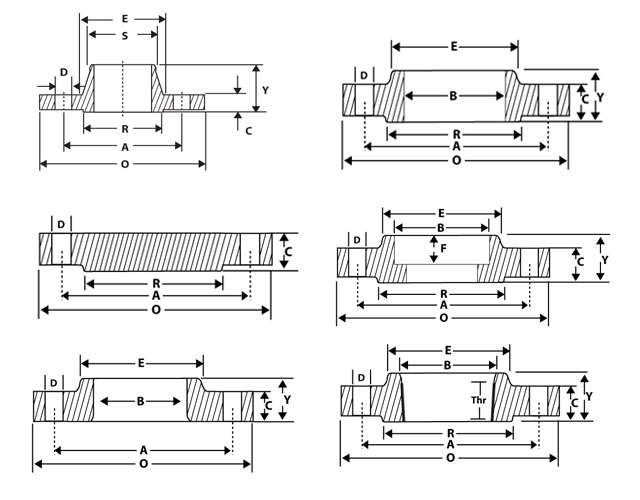

| DIMENSIONS OF CLASS 150 FLANGES (ANSI B 16.5) (in mm) | ||||||||||||||||

| Nominal Pipe Size |

Flange Dia 'O' |

Dia of Bolt Circle 'A' |

Dia of Bolt Holes 'D' |

No. of Holes |

Thk of Flange 'C' |

Diameter at Weld Bevel | Dia of Hub 'E' |

Length Through Hub | Bore 'B' | Dia of R/F R |

Depth of Socket F |

Length of Threading |

||||

| S/O & S/W Y |

W/N Y |

L/J Y |

S/O & S/W B |

L/J B |

||||||||||||

| 1/2'' | 15 | 88.9 | 60.3 | 15.9 | 4 | 11.1 | 21.3 | 30.2 | 15.9 | 47.6 | 15.9 | 22.3 | 22.9 | 34.9 | 9.5 | 15.9 |

| 3/4'' | 20 | 98.4 | 69.8 | 15.9 | 4 | 12.7 | 26.7 | 38.1 | 15.9 | 52.4 | 15.9 | 27.7 | 28.2 | 42.9 | 11.1 | 15.9 |

| 1'' | 25 | 107.9 | 79.4 | 15.9 | 4 | 14.3 | 33.5 | 49.2 | 17.5 | 55.6 | 17.5 | 34.5 | 35.0 | 50.8 | 12.7 | 17.5 |

| 1 ¼'' | 32 | 117.5 | 88.9 | 15.9 | 4 | 15.9 | 42.2 | 58.7 | 20.6 | 57.1 | 20.6 | 43.2 | 43.7 | 63.5 | 14.3 | 20.6 |

| 1 ½'' | 40 | 127.0 | 98.4 | 15.9 | 4 | 17.5 | 48.3 | 65.1 | 22.2 | 61.9 | 22.2 | 49.5 | 50.0 | 73.0 | 15.9 | 22.2 |

| 2'' | 50 | 152.4 | 120.6 | 19.0 | 4 | 19.0 | 60.4 | 77.8 | 25.4 | 63.5 | 25.4 | 62.0 | 62.5 | 92.1 | 17.5 | 25.4 |

| 2 ½'' | 65 | 177.8 | 139.7 | 19.0 | 4 | 22.2 | 73.1 | 90.5 | 28.6 | 69.8 | 28.6 | 74.7 | 75.4 | 104.8 | 19.0 | 28.6 |

| 3'' | 80 | 190.5 | 152.4 | 19.0 | 4 | 23.8 | 88.9 | 107.9 | 30.2 | 69.8 | 30.2 | 90.7 | 91.4 | 127.0 | 20.6 | 30.2 |

| 3 ½'' | 90 | 216.0 | 177.8 | 19.0 | 8 | 23.8 | 101.6 | 122.2 | 31.7 | 71.4 | 31.7 | 103.4 | 104.1 | 140.0 | 20.6 | 31.7 |

| 4'' | 100 | 228.6 | 190.5 | 19.0 | 8 | 23.8 | 114.3 | 134.9 | 33.3 | 76.2 | 33.3 | 116.1 | 116.8 | 157.2 | 23.8 | 33.3 |

| 5'' | 125 | 254.0 | 215.9 | 22.2 | 8 | 23.8 | 141.2 | 163.5 | 36.5 | 88.9 | 36.5 | 143.8 | 144.5 | 185.7 | 23.8 | 36.5 |

| 6'' | 150 | 279.4 | 241.3 | 22.2 | 8 | 25.4 | 168.4 | 192.1 | 39.7 | 88.9 | 39.7 | 170.7 | 171.4 | 215.9 | 27.0 | 39.7 |

| 8'' | 200 | 342.9 | 298.4 | 22.2 | 8 | 28.6 | 219.2 | 246.1 | 44.4 | 101.6 | 44.4 | 221.5 | 222.2 | 269.9 | 31.7 | 44.4 |

| 10'' | 250 | 406.4 | 361.9 | 25.4 | 12 | 30.2 | 273.0 | 304.8 | 49.2 | 101.6 | 49.2 | 276.3 | 277.4 | 323.8 | 33.3 | 49.2 |

| 12'' | 300 | 482.6 | 431.8 | 25.4 | 12 | 31.8 | 323.8 | 365.1 | 55.6 | 114.3 | 55.6 | 327.1 | 328.2 | 381.0 | 39.7 | 55.6 |

| 14'' | 350 | 533.4 | 476.2 | 28.6 | 12 | 34.9 | 355.6 | 400.0 | 57.1 | 127.0 | 79.4 | 359.1 | 360.2 | 412.7 | 41.3 | 57.1 |

| 16'' | 400 | 596.9 | 539.7 | 28.6 | 16 | 36.5 | 406.4 | 457.2 | 63.5 | 127.0 | 87.3 | 410.5 | 411.2 | 469.9 | 44.4 | 63.5 |

| 18'' | 450 | 635.0 | 577.8 | 31.7 | 16 | 39.7 | 457.2 | 504.8 | 68.3 | 139.7 | 96.8 | 461.8 | 462.3 | 533.4 | 49.2 | 68.3 |

| 20'' | 500 | 698.5 | 635.0 | 31.7 | 20 | 42.9 | 508.0 | 558.8 | 73.0 | 144.5 | 103.2 | 513.1 | 514.3 | 584.2 | 54.0 | 73.0 |

| 24'' | 600 | 812.8 | 749.3 | 34.9 | 20 | 47.6 | 609.6 | 663.6 | 82.5 | 152.4 | 111.1 | 615.9 | 615.9 | 692.1 | 63.5 | 82.5 |

| DIMENSIONS OF CLASS 300 FLANGES (ANSI B 16.5) (in mm) | ||||||||||||||||

| Nominal Pipe Size |

Flange Dia 'O' |

Dia of Bolt Circle 'A' |

Dia of Bolt Holes 'D' |

No. of Holes |

Thk of Flange 'C' |

Diameter at Weld Bevel | Dia of Hub 'E' |

Length Through Hub | Bore 'B' | Dia of R/F R |

Depth of Socket F |

Length of Threading |

||||

| S/O & S/W Y |

W/N Y |

L/J Y |

S/O & S/W B |

L/J B |

||||||||||||

| 1/2'' | 15 | 95.2 | 66.7 | 15.9 | 4 | 14.3 | 21.3 | 38.1 | 22.2 | 52.4 | 22.2 | 22.3 | 22.9 | 34.9 | 9.5 | 15.9 |

| 3/4'' | 20 | 117.5 | 82.5 | 19.0 | 4 | 15.9 | 26.7 | 47.6 | 25.4 | 57.1 | 25.4 | 27.7 | 28.2 | 42.9 | 11.1 | 15.9 |

| 1'' | 25 | 123.8 | 88.9 | 19.0 | 4 | 17.5 | 33.5 | 54.0 | 27.0 | 61.9 | 27.0 | 34.5 | 35.0 | 50.8 | 12.7 | 17.5 |

| 1 ¼'' | 32 | 133.3 | 98.4 | 19.0 | 4 | 19.0 | 42.2 | 63.5 | 27.0 | 65.1 | 27.0 | 43.2 | 43.7 | 63.5 | 14.3 | 20.6 |

| 1 ½'' | 40 | 155.6 | 114.3 | 22.2 | 4 | 20.6 | 48.3 | 69.8 | 30.2 | 68.3 | 30.2 | 49.5 | 50.0 | 73.0 | 15.9 | 22.2 |

| 2'' | 50 | 165.1 | 127.0 | 19.0 | 8 | 22.2 | 60.4 | 84.1 | 33.3 | 69.8 | 33.3 | 62.0 | 62.5 | 92.1 | 17.5 | 25.4 |

| 2 ½'' | 65 | 190.5 | 149.2 | 22.2 | 8 | 25.4 | 73.1 | 100.0 | 38.1 | 76.2 | 38.1 | 74.7 | 75.4 | 104.8 | 19.0 | 28.6 |

| 3'' | 80 | 209.5 | 168.3 | 22.2 | 8 | 28.6 | 88.9 | 117.5 | 42.9 | 79.4 | 42.9 | 90.7 | 91.4 | 127.0 | 20.6 | 30.2 |

| 3 ½'' | 90 | 228.5 | 184.2 | 22.2 | 8 | 30.2 | 101.6 | 133.4 | 44.5 | 81.0 | 44.5 | 103.4 | 104.1 | 140.0 | 20.6 | 31.7 |

| 4'' | 100 | 254.0 | 200.0 | 22.2 | 8 | 31.8 | 114.3 | 146.0 | 47.6 | 85.7 | 47.6 | 116.1 | 116.8 | 157.2 | 23.8 | 33.3 |

| 5'' | 125 | 279.4 | 234.9 | 22.2 | 8 | 34.9 | 141.2 | 177.8 | 50.8 | 98.4 | 50.8 | 143.8 | 144.5 | 185.7 | - | 36.5 |

| 6'' | 150 | 317.5 | 269.9 | 22.2 | 12 | 36.5 | 168.4 | 206.4 | 52.4 | 98.4 | 52.4 | 170.7 | 171.4 | 215.9 | - | 39.7 |

| 8'' | 200 | 381.0 | 330.2 | 25.4 | 12 | 41.3 | 219.2 | 260.3 | 61.9 | 111.1 | 61.9 | 221.5 | 222.2 | 269.9 | - | 44.4 |

| 10'' | 250 | 444.5 | 387.3 | 28.6 | 16 | 47.6 | 273.0 | 320.7 | 66.7 | 117.5 | 95.2 | 276.3 | 277.4 | 323.8 | - | 49.2 |

| 12'' | 300 | 520.7 | 450.8 | 31.7 | 16 | 50.8 | 323.8 | 374.6 | 73.0 | 130.2 | 101.6 | 327.1 | 328.2 | 381.0 | - | 55.6 |

| 14'' | 350 | 584.2 | 514.3 | 31.7 | 20 | 54.0 | 355.6 | 425.4 | 76.2 | 142.9 | 111.1 | 359.1 | 360.2 | 412.7 | - | 57.1 |

| 16'' | 400 | 647.7 | 571.5 | 34.9 | 20 | 57.2 | 406.4 | 482.6 | 82.5 | 146.0 | 120.6 | 410.5 | 411.2 | 469.9 | - | 63.5 |

| 18'' | 450 | 711.2 | 628.5 | 34.9 | 24 | 60.3 | 457.2 | 533.4 | 88.9 | 158.7 | 130.2 | 461.8 | 462.3 | 533.4 | - | 68.3 |

| 20'' | 500 | 774.7 | 685.8 | 34.9 | 24 | 63.5 | 508.0 | 587.4 | 95.2 | 161.9 | 139.7 | 513.1 | 514.3 | 584.2 | - | 73.0 |

| 24'' | 600 | 914.4 | 812.8 | 41.3 | 24 | 69.8 | 609.6 | 701.7 | 106.4 | 168.3 | 152.4 | 615.9 | 615.9 | 692.1 | - | 82.5 |

| DIMENSIONS OF CLASS 600 FLANGES (ANSI B 16.5) (in mm) | ||||||||||||||||

| Nominal Pipe Size |

Flange Dia 'O' |

Dia of Bolt Circle 'A' |

Dia of Bolt Holes 'D' |

No. of Holes |

Thk of Flange 'C' |

Diameter at Weld Bevel | Dia of Hub 'E' |

Length Through Hub | Bore 'B' | Dia of R/F R |

Depth of Socket F |

Length of Threading |

||||

| S/O & S/W Y |

W/N Y |

L/J Y |

S/O & S/W B |

L/J B |

||||||||||||

| 1/2'' | 15 | 95.2 | 66.7 | 15.9 | 4 | 14.3 | 21.3 | 38.1 | 22.2 | 52.4 | 22.2 | 22.3 | 22.9 | 34.9 | 9.5 | 15.9 |

| 3/4'' | 20 | 117.5 | 82.5 | 19.0 | 4 | 15.9 | 26.7 | 47.6 | 25.4 | 57.1 | 25.4 | 27.7 | 28.2 | 42.9 | 11.1 | 15.9 |

| 1'' | 25 | 123.8 | 88.9 | 19.0 | 4 | 17.5 | 33.5 | 54.0 | 27.0 | 61.9 | 27.0 | 34.5 | 35.0 | 50.8 | 12.7 | 17.5 |

| 1 ¼'' | 32 | 133.3 | 98.4 | 19.0 | 4 | 20.6 | 42.2 | 63.5 | 28.6 | 66.7 | 28.6 | 43.2 | 43.7 | 63.5 | 14.3 | 20.6 |

| 1 ½'' | 40 | 155.6 | 114.3 | 22.2 | 4 | 22.2 | 48.3 | 69.8 | 31.7 | 69.8 | 31.7 | 49.5 | 50.0 | 73.0 | 15.9 | 22.2 |

| 2'' | 50 | 165.1 | 127.0 | 19.0 | 8 | 25.4 | 60.4 | 84.1 | 36.5 | 73.0 | 36.5 | 62.0 | 62.5 | 92.1 | 17.5 | 25.4 |

| 2 ½'' | 65 | 190.5 | 149.2 | 22.2 | 8 | 28.6 | 73.1 | 100.0 | 41.3 | 79.4 | 41.3 | 74.7 | 75.4 | 104.8 | 19.0 | 28.6 |

| 3'' | 80 | 209.5 | 168.3 | 22.2 | 8 | 31.8 | 88.9 | 117.5 | 46.0 | 82.5 | 46.0 | 90.7 | 91.4 | 127.0 | - | 30.2 |

| 3 ½'' | 90 | 228.5 | 184.2 | 22.2 | 8 | 34.9 | 101.6 | 133.4 | 49.3 | 85.7 | 49.3 | 103.4 | 104.1 | 140.0 | - | 31.7 |

| 4'' | 100 | 273.0 | 215.9 | 25.4 | 8 | 38.1 | 114.3 | 152.4 | 54.0 | 101.6 | 54.0 | 116.1 | 116.8 | 157.2 | - | 33.3 |

| 5'' | 125 | 330.2 | 266.7 | 28.6 | 8 | 44.4 | 141.2 | 188.9 | 60.3 | 114.3 | 60.3 | 143.8 | 144.5 | 185.7 | - | 36.5 |

| 6'' | 150 | 355.6 | 292.1 | 28.6 | 12 | 47.6 | 168.4 | 222.2 | 66.7 | 117.5 | 66.7 | 170.7 | 171.4 | 215.9 | - | 39.7 |

| 8'' | 200 | 419.1 | 349.2 | 31.7 | 12 | 55.6 | 219.2 | 273.0 | 76.2 | 133.3 | 76.2 | 221.5 | 222.2 | 269.9 | - | 44.4 |

| 10'' | 250 | 508.0 | 431.8 | 34.9 | 16 | 63.5 | 273.0 | 342.9 | 85.7 | 152.4 | 111.2 | 276.3 | 277.4 | 323.8 | - | 49.2 |

| 12'' | 300 | 558.8 | 488.9 | 34.9 | 20 | 66.7 | 323.8 | 400.0 | 92.1 | 155.6 | 117.3 | 327.1 | 328.2 | 381.0 | - | 55.6 |

| 14'' | 350 | 603.2 | 527.0 | 38.1 | 20 | 69.9 | 355.6 | 431.8 | 93.7 | 165.1 | 127.0 | 359.1 | 360.2 | 412.7 | - | 57.1 |

| 16'' | 400 | 685.8 | 603.2 | 41.3 | 20 | 76.2 | 406.4 | 495.3 | 106.4 | 177.8 | 139.7 | 410.5 | 411.2 | 469.9 | - | 63.5 |

| 18'' | 450 | 742.9 | 654.0 | 44.4 | 24 | 82.6 | 457.2 | 546.1 | 117.5 | 184.1 | 152.4 | 461.8 | 462.3 | 533.4 | - | 68.3 |

| 20'' | 500 | 812.8 | 723.9 | 44.4 | 24 | 88.9 | 508.0 | 609.6 | 127.0 | 190.5 | 165.1 | 513.1 | 514.3 | 584.2 | - | 73.0 |

| 24'' | 600 | 939.8 | 838.2 | 50.8 | 24 | 101.6 | 609.6 | 717.5 | 139.7 | 203.2 | 184.1 | 615.9 | 615.9 | 692.1 | - | 82.5 |

| DIMENSIONS OF CLASS 900 FLANGES (ANSI B 16.5) (in mm) | ||||||||||||||||

| Nominal Pipe Size |

Flange Dia 'O' |

Dia of Bolt Circle 'A' |

Dia of Bolt Holes 'D' |

No. of Holes |

Thk of Flange 'C' |

Diameter at Weld Bevel | Dia of Hub 'E' |

Length Through Hub | Bore 'B' | Dia of R/F R |

Depth of Socket F |

Length of Threading |

||||

| S/O & S/W Y |

W/N Y |

L/J Y |

S/O & S/W B |

L/J B |

||||||||||||

| 1/2'' | 15 | 95.2 | 66.7 | 15.9 | 4 | 14.3 | 21.3 | 38.1 | 22.2 | 52.4 | 22.2 | 22.3 | 22.9 | 34.9 | 9.5 | 15.9 |

| 3/4'' | 20 | 117.5 | 82.5 | 19.0 | 4 | 15.9 | 26.7 | 47.6 | 25.4 | 57.1 | 25.4 | 27.7 | 28.2 | 42.9 | 11.1 | 15.9 |

| 1'' | 25 | 123.8 | 88.9 | 19.0 | 4 | 17.5 | 33.5 | 54.0 | 27.0 | 61.9 | 27.0 | 34.5 | 35.0 | 50.8 | 12.7 | 17.5 |

| 1 ¼'' | 32 | 133.3 | 98.4 | 19.0 | 4 | 20.6 | 42.2 | 63.5 | 28.6 | 66.7 | 28.6 | 43.2 | 43.7 | 63.5 | 14.3 | 20.6 |

| 1 ½'' | 40 | 155.6 | 114.3 | 22.2 | 4 | 22.2 | 48.3 | 69.8 | 31.7 | 69.8 | 31.7 | 49.5 | 50.0 | 73.0 | 15.9 | 22.2 |

| 2'' | 50 | 165.1 | 127.0 | 19.0 | 8 | 25.4 | 60.4 | 84.1 | 36.5 | 73.0 | 36.5 | 62.0 | 62.5 | 92.1 | 17.5 | 25.4 |

| 2 ½'' | 65 | 190.5 | 149.2 | 22.2 | 8 | 28.6 | 73.1 | 100.0 | 41.3 | 79.4 | 41.3 | 74.7 | 75.4 | 104.8 | 19.0 | 28.6 |

| 3'' | 80 | 209.5 | 168.3 | 22.2 | 8 | 31.8 | 88.9 | 117.5 | 46.0 | 82.5 | 46.0 | 90.7 | 91.4 | 127.0 | - | 30.2 |

| 3 ½'' | 90 | 228.5 | 184.2 | 22.2 | 8 | 34.9 | 101.6 | 133.4 | 49.3 | 85.7 | 49.3 | 103.4 | 104.1 | 140.0 | - | 31.7 |

| 4'' | 100 | 273.0 | 215.9 | 25.4 | 8 | 38.1 | 114.3 | 152.4 | 54.0 | 101.6 | 54.0 | 116.1 | 116.8 | 157.2 | - | 33.3 |

| 5'' | 125 | 330.2 | 266.7 | 28.6 | 8 | 44.4 | 141.2 | 188.9 | 60.3 | 114.3 | 60.3 | 143.8 | 144.5 | 185.7 | - | 36.5 |

| 6'' | 150 | 355.6 | 292.1 | 28.6 | 12 | 47.6 | 168.4 | 222.2 | 66.7 | 117.5 | 66.7 | 170.7 | 171.4 | 215.9 | - | 39.7 |

| 8'' | 200 | 419.1 | 349.2 | 31.7 | 12 | 55.6 | 219.2 | 273.0 | 76.2 | 133.3 | 76.2 | 221.5 | 222.2 | 269.9 | - | 44.4 |

| 10'' | 250 | 508.0 | 431.8 | 34.9 | 16 | 63.5 | 273.0 | 342.9 | 85.7 | 152.4 | 111.2 | 276.3 | 277.4 | 323.8 | - | 49.2 |

| 12'' | 300 | 558.8 | 488.9 | 34.9 | 20 | 66.7 | 323.8 | 400.0 | 92.1 | 155.6 | 117.3 | 327.1 | 328.2 | 381.0 | - | 55.6 |

| 14'' | 350 | 603.2 | 527.0 | 38.1 | 20 | 69.9 | 355.6 | 431.8 | 93.7 | 165.1 | 127.0 | 359.1 | 360.2 | 412.7 | - | 57.1 |

| 16'' | 400 | 685.8 | 603.2 | 41.3 | 20 | 76.2 | 406.4 | 495.3 | 106.4 | 177.8 | 139.7 | 410.5 | 411.2 | 469.9 | - | 63.5 |

| 18'' | 450 | 742.9 | 654.0 | 44.4 | 24 | 82.6 | 457.2 | 546.1 | 117.5 | 184.1 | 152.4 | 461.8 | 462.3 | 533.4 | - | 68.3 |

| 20'' | 500 | 812.8 | 723.9 | 44.4 | 24 | 88.9 | 508.0 | 609.6 | 127.0 | 190.5 | 165.1 | 513.1 | 514.3 | 584.2 | - | 73.0 |

| 24'' | 600 | 939.8 | 838.2 | 50.8 | 24 | 101.6 | 609.6 | 717.5 | 139.7 | 203.2 | 184.1 | 615.9 | 615.9 | 692.1 | - | 82.5 |

| DIMENSIONS OF CLASS 1500 FLANGES (ANSI B 16.5) (in mm) | ||||||||||||||||

| Nominal Pipe Size |

Flange Dia 'O' |

Dia of Bolt Circle 'A' |

Dia of Bolt Holes 'D' |

No. of Holes |

Thk of Flange 'C' |

Diameter at Weld Bevel | Dia of Hub 'E' |

Length Through Hub | Bore 'B' | Dia of R/F R |

Depth of Socket F |

Length of Threading |

||||

| S/O & S/W Y |

W/N Y |

L/J Y |

S/O & S/W B |

L/J B |

||||||||||||

| 1/2'' | 15 | 120.6 | 82.5 | 22.2 | 4 | 22.2 | 21.3 | 38.1 | 31.7 | 60.3 | 31.7 | 22.3 | 22.9 | 34.9 | 9.5 | 22.2 |

| 3/4'' | 20 | 130.2 | 88.9 | 22.2 | 4 | 25.4 | 26.7 | 44.4 | 34.9 | 69.8 | 34.9 | 27.7 | 28.2 | 42.9 | 11.1 | 25.4 |

| 1'' | 25 | 149.2 | 101.6 | 25.4 | 4 | 28.6 | 33.5 | 52.4 | 41.3 | 73.0 | 41.3 | 34.5 | 35.0 | 50.8 | 12.7 | 28.6 |

| 1 ¼'' | 32 | 158.7 | 111.1 | 25.4 | 4 | 28.6 | 42.2 | 63.5 | 41.3 | 73.0 | 41.3 | 43.2 | 43.7 | 63.5 | 14.3 | 30.2 |

| 1 ½'' | 40 | 177.8 | 123.8 | 28.6 | 4 | 31.8 | 48.3 | 69.8 | 44.4 | 82.5 | 44.4 | 49.5 | 50.0 | 73.0 | 15.9 | 31.7 |

| 2'' | 50 | 215.9 | 165.1 | 25.4 | 8 | 38.1 | 60.4 | 104.8 | 57.1 | 101.6 | 57.1 | 62.0 | 62.5 | 92.1 | 17.5 | 38.1 |

| 2 ½'' | 65 | 244.5 | 190.5 | 28.6 | 8 | 41.3 | 73.1 | 123.8 | 63.5 | 123.8 | 63.5 | 74.7 | 75.4 | 104.8 | 19.0 | 47.6 |

| 3'' | 80 | 266.7 | 203.2 | 31.7 | 8 | 47.6 | 88.9 | 133.3 | 73.0 | 117.5 | 73.0 | 90.7 | 91.4 | 127.0 | - | 50.8 |

| 4'' | 100 | 311.1 | 241.3 | 34.9 | 8 | 54.0 | 114.3 | 161.9 | 90.5 | 123.0 | 90.5 | 116.1 | 116.8 | 157.2 | - | 57.1 |

| 5'' | 125 | 374.6 | 292.1 | 41.3 | 8 | 73.0 | 141.2 | 196.8 | 104.8 | 155.6 | 104.8 | 143.8 | 144.5 | 185.7 | - | 63.5 |

| 6'' | 150 | 393.7 | 317.5 | 38.1 | 12 | 82.6 | 168.4 | 228.6 | 119.1 | 171.4 | 119.1 | 170.7 | 171.4 | 215.9 | - | 69.8 |

| 8'' | 200 | 482.6 | 393.7 | 44.4 | 12 | 92.1 | 219.2 | 292.1 | 142.9 | 212.7 | 142.8 | 221.5 | 222.2 | 269.9 | - | 76.2 |

| 10'' | 250 | 584.2 | 482.6 | 50.8 | 12 | 107.9 | 273.0 | 368.3 | 158.7 | 254.0 | 177.8 | 276.3 | 277.4 | 323.8 | - | 84.1 |

| 12'' | 300 | 673.1 | 571.5 | 54.0 | 16 | 123.8 | 323.8 | 450.8 | 181.0 | 282.5 | 219.1 | 327.1 | 328.2 | 381.0 | - | 92.1 |

| 14'' | 350 | 749.5 | 635.0 | 60.5 | 16 | 133.4 | 355.6 | 495.3 | - | 298.5 | 241.3 | 359.1 | 360.2 | 412.7 | - | - |

| 16'' | 400 | 825.5 | 704.9 | 66.5 | 16 | 146.1 | 406.4 | 552.5 | - | 311.2 | 260.4 | 410.5 | 411.2 | 469.9 | - | - |

| 18'' | 450 | 914.5 | 774.7 | 73.5 | 16 | 162.0 | 457.2 | 596.9 | - | 327.0 | 276.2 | 461.8 | 462.3 | 533.4 | - | - |

| 20'' | 500 | 984.0 | 831.9 | 79.5 | 16 | 177.8 | 508.0 | 641.4 | - | 355.6 | 292.1 | 513.1 | 514.3 | 584.2 | - | - |

| 24'' | 600 | 1168.5 | 990.6 | 92.0 | 16 | 203.2 | 609.6 | 762.0 | - | 406.4 | 330.2 | 615.9 | 615.9 | 692.1 | - | - |

| DIMENSIONS OF CLASS 2500 FLANGES (ANSI B 16.5) (in mm) | ||||||||||||||||

| Nominal Pipe Size |

Flange Dia 'O' |

Dia of Bolt Circle 'A' |

Dia of Bolt Holes 'D' |

No. of Holes |

Thk of Flange 'C' |

Diameter at Weld Bevel | Dia of Hub 'E' |

Length Through Hub | Bore 'B' | Dia of R/F R |

Depth of Socket F |

Length of Threading |

||||

| S/O & S/W Y |

W/N Y |

L/J Y |

S/O & S/W B |

L/J B |

||||||||||||

| 1/2'' | 15 | 133.3 | 88.9 | 22.2 | 4 | 30.2 | 21.3 | 42.9 | 39.7 | 73.3 | 39.7 | 22.3 | 22.9 | 34.9 | - | 28.6 |

| 3/4'' | 20 | 139.7 | 95.2 | 22.2 | 4 | 31.7 | 26.7 | 50.8 | 42.9 | 79.4 | 42.9 | 27.7 | 28.2 | 42.9 | - | 31.7 |

| 1'' | 25 | 158.7 | 107.9 | 25.4 | 4 | 34.9 | 33.5 | 57.1 | 47.7 | 88.9 | 47.7 | 34.5 | 35.0 | 50.8 | - | 34.9 |

| 1 ¼'' | 32 | 184.1 | 130.2 | 28.6 | 4 | 38.1 | 42.2 | 73.0 | 52.4 | 95.2 | 52.4 | 43.2 | 43.7 | 63.5 | - | 38.1 |

| 1 ½'' | 40 | 203.2 | 146.0 | 31.7 | 4 | 44.4 | 48.3 | 79.4 | 60.3 | 111.1 | 60.3 | 49.5 | 50.0 | 73.0 | - | 44.4 |

| 2'' | 50 | 234.9 | 171.4 | 28.6 | 8 | 50.8 | 60.4 | 95.2 | 69.8 | 127.0 | 69.8 | 62.0 | 62.5 | 92.1 | - | 50.8 |

| 2 ½'' | 65 | 266.7 | 196.8 | 31.7 | 8 | 57.1 | 73.1 | 114.3 | 79.4 | 142.9 | 79.4 | 74.7 | 75.4 | 104.8 | - | 57.1 |

| 3'' | 80 | 304.8 | 228.6 | 34.9 | 8 | 66.7 | 88.9 | 133.3 | 92.1 | 168.3 | 92.1 | 90.7 | 91.4 | 127.0 | - | 63.5 |

| 4'' | 100 | 355.6 | 273.0 | 41.3 | 8 | 76.2 | 114.3 | 165.1 | 107.9 | 190.5 | 107.9 | 116.1 | 116.8 | 157.2 | - | 69.8 |

| 5'' | 125 | 419.1 | 323.8 | 47.6 | 8 | 92.1 | 141.2 | 203.2 | 130.0 | 128.6 | 130.0 | 143.8 | 144.5 | 185.7 | - | 76.2 |

| 6'' | 150 | 482.6 | 368.3 | 54.0 | 8 | 107.9 | 168.4 | 234.9 | 152.4 | 273.0 | 152.4 | 170.7 | 171.4 | 215.9 | - | 82.5 |

| 8'' | 200 | 552.4 | 438.1 | 54.0 | 12 | 127.0 | 219.2 | 304.8 | 177.8 | 317.5 | 177.8 | 221.5 | 222.2 | 269.9 | - | 95.2 |

| 10'' | 250 | 673.1 | 539.7 | 66.7 | 12 | 165.1 | 273.0 | 374.6 | 228.6 | 419.1 | 228.6 | 276.3 | 277.4 | 323.8 | - | 107.9 |

| 12'' | 300 | 762.0 | 619.1 | 73.0 | 12 | 184.1 | 323.8 | 441.3 | 254.0 | 463.5 | 254.0 | 327.1 | 328.2 | 381.0 | - | 120.6 |

WELDING NECK FLANGES BORES (in inchines)

|

||||||||||||||

| Nom Pipe Size |

Outside Diam |

Sched 10 |

Sched 20 |

Sched 30 |

Std. Wall |

Sched 40 |

Sched 60 |

Extra Strong |

Sched 80 |

Sched 100 |

Sched 120 |

Sched 140 |

Sched 160 |

Double Extra Strong |

| 1/2'' | 0.840 | 0.674 | - | - | 0.622 | 0.622 | - | 0.546 | 0.546 | - | - | - | 0.464 | 0.252 |

| 3/4'' | 1.050 | 0.884 | - | - | 0.824 | 0.824 | - | 0.742 | 0.742 | - | - | - | 0.612 | 0.434 |

| 1'' | 1.315 | 1.097 | - | - | 1.049 | 1.049 | - | 0.957 | 0.957 | - | - | - | 0.815 | 0.599 |

| 1.1/4'' | 1.660 | 1.442 | - | - | 1.380 | 1.380 | - | 1.278 | 1.278 | - | - | - | 1.160 | 0.896 |

| 1.1/2'' | 1.900 | 1.682 | - | - | 1.610 | 1.610 | - | 1.500 | 1.500 | - | - | - | 1.338 | 1.100 |

| 2'' | 2.375 | 2.157 | - | - | 2.067 | 2.067 | - | 1.939 | 1.939 | - | - | - | 1.687 | 1.503 |

| 2.1/2'' | 2.875 | 2.635 | - | - | 2.469 | 2.469 | - | 2.323 | 2.323 | - | - | - | 2.125 | 1.771 |

| 3'' | 3.500 | 3.260 | - | - | 3.068 | 3.068 | - | 2.900 | 2.900 | - | - | - | 2.624 | 2.300 |

| 3-1/2'' | 4.000 | 3.760 | - | - | 3.548 | 3.548 | - | 3.364 | 3.364 | - | - | - | - | 2.728 |

| 4'' | 4.500 | 4.260 | - | - | 4.026 | 4.026 | - | 3.826 | 3.826 | - | 3.624 | - | 3.438 | 3.152 |

| 5'' | 5.563 | 5.295 | - | - | 5.047 | 5.047 | - | 4.813 | 4.813 | - | 4.563 | - | 4.313 | 4.063 |

| 6'' | 6.625 | 6.357 | - | - | 6.065 | 6.065 | - | 5.761 | 5.761 | - | 5.501 | - | 5.187 | 4.897 |

| 8'' | 8.625 | 8.329 | 8.125 | 8.071 | 7.981 | 7.981 | 7.813 | 7.625 | 7.625 | 7.437 | 7.187 | 7.001 | 6.813 | 6.875 |

| 10'' | 10.750 | 10.420 | 10.250 | 10.136 | 10.020 | 10.020 | 9.750 | 9.750 | 9.562 | 9.312 | 9.062 | 8.750 | 8.500 | 8.750 |

| 12'' | 12.750 | 10.420 | 10.250 | 12.090 | 12.000 | 11.938 | 11.626 | 11.750 | 11.374 | 11.062 | 10.750 | 10.500 | 10.126 | 10.750 |

| 14'' | 14.000 | 13.500 | 13.376 | 13.250 | 13.250 | 13.124 | 12.812 | 13.000 | 12.500 | 12.124 | 11.814 | 11.500 | 11.188 | - |

| 16'' | 16.000 | 15.500 | 15.376 | 15.250 | 15.250 | 15.000 | 14.688 | 15.000 | 14.312 | 13.938 | 13.564 | 13.124 | 12.812 | - |

| 18'' | 18.000 | 17.500 | 17.376 | 17.124 | 17.250 | 16.876 | 16.500 | 17.000 | 16.124 | 15.688 | 15.250 | 14.876 | 14.438 | - |

| 20'' | 20.000 | 19.500 | 19.250 | 19.000 | 19.250 | 18.812 | 18.376 | 19.000 | 17.938 | 17.438 | 17.000 | 16.500 | 16.062 | - |

| 24'' | 24.000 | 23.500 | 23.250 | 22.876 | 23.250 | 22.624 | 22.062 | 23.000 | 21.562 | 20.938 | 20.376 | 19.876 | 19.312 | - |

| 30'' | 30.000 | 29.376 | 29.000 | 28.750 | 29.250 | - | - | 29.000 | - | - | - | - | - | - |

| 36'' | 36.000 | 35.376 | 35.000 | 34.750 | 35.250 | 34.500 | - | 35.000 | - | - | - | - | - | - |

| 42'' | 42.000 | - | - | - | 41.250 | - | - | 41.000 | - | - | - | - | - | - |

| ANSI FLANGES WEIGHT (KGS) | ||||||||||||||||||

| Nom Pipe Size |

150# | 300# | 600# | 900# | 1500# | 2500# | ||||||||||||

| WN | S/O | B/K | WN | S/O | B/K | WN | S/O | B/K | WN | S/O | B/K | WN | S/O | B/K | WN | S/O | B/K | |

| 1/2'' | 0.7 | 0.4 | 0.5 | 0.8 | 0.7 | 0.8 | 0.9 | 0.8 | 0.8 | 2.1 | 1.8 | 1.9 | 2.1 | 1.8 | 1.9 | 3.2 | 3 | 3 |

| 3/4'' | 0.8 | 0.7 | 0.8 | 1.4 | 1.2 | 1.2 | 1.6 | 1.4 | 1.4 | 2.7 | 2.4 | 2.7 | 2.7 | 2.4 | 2.7 | 3.6 | 4 | 4.5 |

| 1'' | 1.1 | 0.8 | 0.9 | 1.7 | 1.4 | 1.5 | 1.9 | 1.7 | 1.7 | 3.9 | 3.6 | 3.7 | 3.9 | 3.6 | 3.7 | 5.4 | 5 | 5 |

| 1.1/4'' | 1.5 | 1.2 | 1.3 | 2.2 | 1.8 | 2 | 2.6 | 2.1 | 2.4 | 4.5 | 4.1 | 4.3 | 4.5 | 4.1 | 4.3 | 7.8 | 8 | 8 |

| 1.1/2'' | 1.8 | 1.4 | 1.6 | 3.2 | 2.7 | 2.9 | 3.6 | 3.1 | 3.4 | 6.2 | 5.4 | 5.9 | 6.2 | 5.4 | 5.9 | 11.5 | 11 | 11 |

| 2'' | 2.7 | 2.2 | 2.6 | 3.6 | 3.2 | 3.5 | 4.7 | 3.9 | 4.4 | 11.3 | 10.5 | 11.3 | 11.3 | 10.5 | 11.3 | 19 | 17 | 17 |

| 2.1/2'' | 4.4 | 3.5 | 4.1 | 5.4 | 4.5 | 5.3 | 4.8 | 5.4 | 6.8 | 16.3 | 15.8 | 16 | 16.3 | 15.8 | 16 | 24 | 25 | 25 |

| 3'' | 5.2 | 3.8 | 5.1 | 7.3 | 5.9 | 7.2 | 8.7 | 7.3 | 8.9 | 15 | 12.3 | 16.8 | 21 | 21.5 | 19.5 | 42.6 | 38 | 39 |

| 3-1/2'' | 6.4 | 5 | 6.5 | 8.9 | 7.5 | 9.2 | 11.6 | 9 | 12.7 | - | - | - | - | - | - | - | - | - |

| 4'' | 7.5 | 5.6 | 7.5 | 11.8 | 10 | 12.2 | 18.4 | 16.5 | 18.6 | 24 | 23.2 | 24.5 | 31.8 | 31 | 33 | 64 | 58 | 60 |

| 5'' | 9.2 | 6.5 | 9.2 | 16 | 12.5 | 16 | 31 | 28.5 | 30.8 | 38.5 | 37.5 | 39.5 | 59 | 58.8 | 60 | 111 | 95 | 101 |

| 6'' | 11.0 | 8.1 | 11.8 | 20.2 | 16.5 | 22 | 37 | 36.2 | 38 | 50 | 48.3 | 51.5 | 72 | 74 | 75 | 171 | 146 | 156 |

| 8'' | 18.4 | 13 | 20.4 | 31.2 | 25.5 | 36 | 54.5 | 51.5 | 62.2 | 85 | 75 | 89 | 124 | 112 | 125 | 261 | 220 | 242 |

| 10'' | 25.5 | 18.4 | 31 | 44.3 | 35 | 55 | 98.5 | 76.2 | 102 | 123 | 110 | 131 | 207 | 184 | 215 | 485 | 420 | 465 |

| 12'' | 37 | 28.5 | 47 | 63.5 | 52 | 82.5 | 105 | 89.5 | 132 | 168 | 146 | 187 | 306 | 264 | 316 | 698 | 590 | 665 |

| 14'' | 51 | 37.5 | 60 | 86 | 73 | 108 | 150 | 102 | 158 | 198 | 172 | 224 | 416 | - | - | - | - | - |

| 16'' | 61.5 | 44.5 | 61 | 112 | 88 | 139 | 177 | 150 | 225 | 225 | 192 | 259 | 567 | - | - | - | - | - |

| 18'' | 71.5 | 54 | 93 | 141 | 115 | 178 | 228 | 180 | 285 | 318 | 272 | 383 | 736 | - | - | - | - | - |

| 20'' | 85 | 72 | 127 | 173 | 139 | 228 | 285 | 231 | 365 | 376 | 330 | 482 | 929 | - | - | - | - | - |

| 24'' | 119 | 95 | 190 | 248 | 212 | 350 | 372 | 330 | 532 | 680 | 632 | 905 | 1504 | - | - | - | - | - |

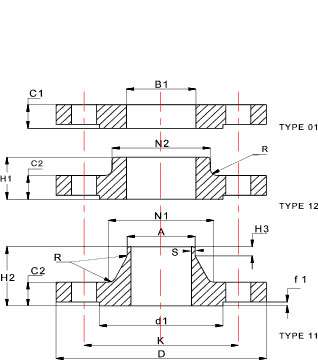

Weldneck flanges have drilled wall thickness which is of equally same dimension existing for matching pipe. Bore will be larger if the pipe is lighter and opposite will be true if pipe is heavier and the bore will be small.

Erosion as well as turbulence is significantly reduced in pipeline as bores of flange & pipe match. Due to these reasons weldneck flanges are chosen for critical applications where high pressure and hot-cold temperatures are prevalent. The different kinds of weldneck flanges available are:

- Weld neck flanges - raised face

- Weld neck flanges - flat face

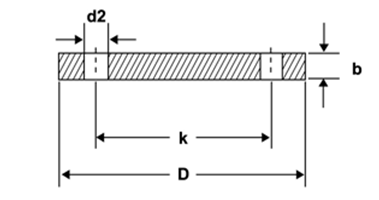

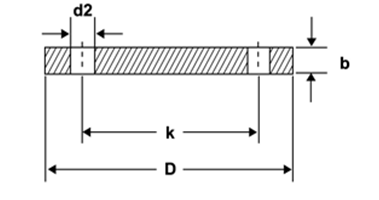

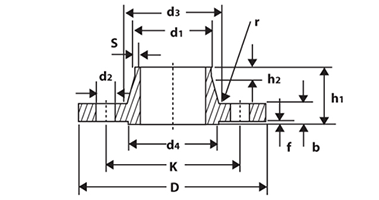

| DIMENSIONS TOLERANCES OF FLANGES (in mm) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| H Not covered by ANSI - B 16.5 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Table

D for W. Steam Pressure upto 50 lbs per Sq. Inch (in inchines) |

Table E for W. Steam Pressure 50 lbs and upto 100 lbs per Sq. Inch (in inchines) | ||||||||||||||

| Nominal |

Dia. of Flange |

I.D. of Flange | Dia. of Bolt Circle |

No. of |

Dia. of Bolt |

Thickness | Nominal |

Dia. of Flange |

I.D. of Flange | Dia. of Bolt Circle |

No. of |

Dia. of Bolt |

Thickness | ||

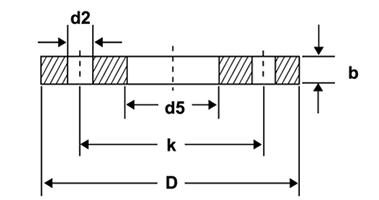

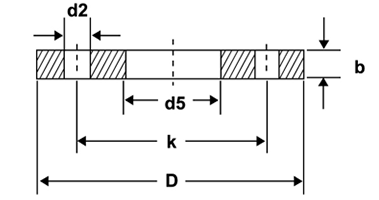

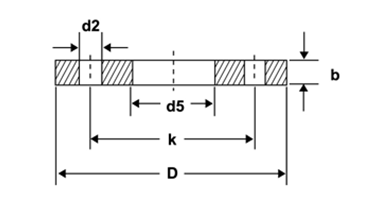

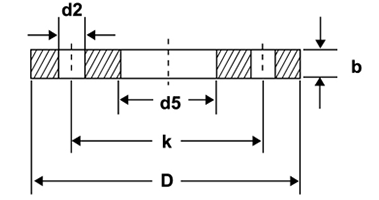

| Pipe Size | D | d5 | k | Holes | d2 | b | Pipe Size | D | d5 | k | Holes | d2 | b | ||

| 1/2" | 3.3/4" | 7/8" | 2.5/8" | 4 | 1/2" | 3/16" | 1/2" | 3.3/4" | 7/8" | 2.5/8" | 4 | 1/2" | 1/4" | ||

| 3/4" | 4" | 1.3/32" | 2.7/8" | 4 | 1/2" | 3/16" | 3/4" | 4" | 1.3/32" | 2.7/8" | 4 | 1/2" | 1/4" | ||

| 1" | 4.1/2" | 1.23/64" | 3.1/4" | 4 | 1/2" | 3/16" | 1" | 4.1/2" | 1.23/64" | 3.1/4" | 4 | 1/2" | 9/32" | ||

| 1.1/4" | 4.3/4" | 1.45/64" | 3.7/16" | 4 | 1/2" | 1/4" | 1.1/4" | 4.3/4" | 1.45/64" | 3.7/16" | 4 | 1/2" | 5/16" | ||

| 1.1/2" | 5.1/4" | 1.15/16" | 3.7/8" | 4 | 1/2" | 1/4" | 1.1/2" | 5.1/4" | 1.15/16" | 3.7/8" | 4 | 1/2" | 11/32" | ||

| 2" | 6" | 2.7/16" | 4.1/2" | 4 | 5/8" | 5/16" | 2" | 6" | 2.7/16" | 4.1/2" | 4 | 5/8" | 3/8" | ||

| 2.1/2 | 6.1/2" | 2.15/16" | 5" | 4 | 5/8" | 5/16" | 2.1/2" | 6.1/2" | 2.15/16" | 5" | 4 | 5/8" | 13/32" | ||

| 3" | 7.1/4" | 3.37/64" | 5.3/4" | 4 | 5/8" | 3/8" | 3" | 7.1/4" | 3.37/64" | 5.3/4" | 4 | 5/8" | 7/16" | ||

| 3.1/2" | 8" | 4.5/64" | 6.1/2" | 4 | 5/8" | 3/8" | 3.1/2" | 8" | 4.5/64" | 6.1/2" | 8 | 5/8" | 15/32" | ||

| 4" | 8.1/2" | 4.37/64" | 7" | 4 | 5/8" | 3/8" | 4" | 8.1/2" | 4.37/64" | 7" | 8 | 5/8" | 1/2" | ||

| 5" | 10" | 5.43/64" | 8.1/4" | 8 | 5/8" | 1/2" | 5" | 10" | 5.43/64" | 8.1/4" | 8 | 5/8" | 9/16" | ||

| 6" | 11" | 6.23/32" | 9.1/4" | 8 | 5/8" | 1/2" | 6" | 11" | 6.23/32" | 9.1/4" | 8 | 3/4" | 11/16" | ||

| 7" | 12" | 7.5/8" | 10.1/4" | 8 | 5/8" | 1/2" | 7" | 12" | 7.5/8" | 10.1/4" | 8 | 3/4" | 3/4" | ||

| 8' | 13.1/4" | 8.23/32" | 11.1/2" | 8 | 5/8" | 1/2" | 8" | 12.1/4" | 8.23/32" | 11.1/2" | 8 | 3/4" | 3/4" | ||

| 9" | 14.1/2" | 9.23/32" | 12.3/4" | 8 | 5/8" | /8" | 9" | 14.1/2" | 9.23/32" | 12.3/4" | 12 | 3/4" | 13/16" | ||

| 10" | 16" | 10.7/8" | 14" | 8 | 3/4" | 5/8"> | 10" | 16" | 10.7/8" | 14" | 12 | 3/4" | 7/8" | ||

| 12" | 18" | 12.7/8" | 16" | 12 | 3/4" | 5/8" | 12" | 18" | 12.7/8" | 16" | 12 | 7/8" | 1" | ||

| 14" | 20.3/4" | 14.9/64" | 18.1/2" | 12 | 7/8" | 3/4" | 4" | 20.3/4" | 14.9/64" | 18.1/2" | 12 | 7/8" | 1" | ||

| 16" | 22.3/4" | 16.5/32" | 20.1/2" | 12 | 7/8" | 3/4" | 6" | 22.3/4" | 16.5/32" | 20.1/2" | 12 | 7/8" | 1" | ||

| 18" | 25.1/4" | 18.3/16" | 23" | 12 | 7/8" | 7/8" | 18" | 25.1/4" | 18.3/16" | 23" | 16 | 7/8" | 1.1/8" | ||

| 20" | 27.3/4" | 20.13/16" | 25.1/4" | 16 | 7/8" | 1" | 20" | 27.3/4" | 20.13/16" | 25.1/4" | 16 | 7/8" | 1.1/4" | ||

| 24" | 32.1/2" | 24.1/4" | 29.3/4" | 16 | 1" | 1.1/8" | 24" | 32.1/2" | 24.1/4" | 29.3/4" | 16 | 1" | 1.1/2" | ||

| Table

F for W. Steam Pressure 100 lbs per Sq. Inch (in inchines) |

Table

H for W. Steam Pressure 150 lbs and upto 250 lbs per Sq. Inch (in inchines) |

|||||||||||||

| Nominal |

Dia. of Flange |

I.D. of Flange | Dia. of Bolt Circle |

No. of |

Dia. of Bolt |

Thickness | Nominal |

Dia. of Flange |

I.D. of Flange | Dia. of Bolt Circle |

No. of |

Dia. of Bolt |

Thickness | |

| Pipe Size | D | d5 | k | Holes | d2 | b | Pipe Size | D | d5 | k | Holes | d2 | b | |

| 1/2" | 3.3/4" | 7/8" | 2.5/8" | 4 | 1/2" | 3/8" | 1/2" | 4.1/2" | 7/8" | 3.1/4" | 4 | 5/8" | 1/2" | |

| 3/4" | 4" | 1.3/32" | 2.7/8" | 4 | 1/2" | 3/8" | 3/4" | 4.1/2" | 1.3/32" | 3.1/4" | 4 | 5/8" | 1/2" | |

| 1" | 4.3/4" | 1.23/64" | 3.7/16" | 4 | 5/8" | 3/8" | 1" | 4.3/4" | 1.23/64" | 33.7/16" | 4 | 5/8" | 9/16" | |

| 1.1/4" | 5.1/4" | 1.45/64" | 3.7/8" | 4 | 5/8" | 1/2" | 1.1/4" | 5.1/4" | 1.45/64" | 3.7/8" | 4 | 5/8" | 11/16" | |

| 1.1/2" | 5.1/2" | 1.15/16" | 4.1/8" | 4 | 5/8" | 1/2" | 1.1/2" | 5.1/2" | 1.15/16" | 4.1/8" | 4 | 5/8" | 11/16" | |

| 2" | 6.1/2" | 2.7/16" | 5" | 4 | 5/8" | 5/8" | 2" | 6.1/2" | 2.7/16" | 5" | 4 | 5/8" | 3/4" | |

| 2.1/2 | 7.1/4" | 2.15/16" | 5.3/4" | 8 | 5/8" | 5/8" | 2.1/2" | 7.1/4" | 2.15/16" | 5.3/4" | 8 | 5/8" | 3/4" | |

| 3" | 8" | 3.37/64" | 6.1/2" | 8 | 5/8" | 5/8" | 3" | 8" | 3.37/64" | 6.1/2" | 8 | 5/8" | 7/8" | |

| 3.1/2" | 8.1/2" | 4.5/64" | 7" | 8 | 5/8" | 3/4" | 3.1/2" | 8.1/2" | 4.5/64" | 7" | 8 | 5/8" | 7/8" | |

| 4" | 9" | 4.37/64" | 7.1/2" | 8 | 5/8" | 3/4" | 4" | 9" | 4.37/64" | 7.1/2" | 8 | 5/8" | 1" | |

| 5" | 11" | 5.43/64" | 9.1/4" | 8 | 3/4" | 7/8" | 5" | 11" | 5.43/64" | 9.1/4" | 8 | 3/4" | 1.1/8" | |

| 6" | 12" | 6.23/32" | 10.1/4" | 12 | 3/4" | 7/8" | 6" | 12" | 6.23/32" | 10.1/4" | 12 | 3/4" | 1.1/8" | |

| 7" | 13.1/4" | 7.5/8" | 11.1/2" | 12 | 3/4" | 7/8" | 7" | 13.1/4" | 7.5/8" | 11.1/2" | 12 | 3/4" | 1.1/4" | |

| 8' | 14.1/2" | 8.23/32" | 12.3/4" | 12 | 3/4" | 1" | 8" | 14.1/2" | 8.23/32" | 12.3/4" | 12 | 3/4" | 1.1/4" | |

| 9" | 16" | 9.23/32" | 14" | 12 | 7/8" | 1" | 9" | 16" | 9.23/32" | 14" | 12 | 7/8" | 1.3/8" | |

| 10" | 17" | 10.7/8" | 15" | 12 | 7/8" | 1" | 10" | 17" | 10.7/8" | 15" | 12 | 7/8" | 1.3/8" | |

| 12" | 19.1/4" | 12.7/8" | 17.1/4" | 16 | 7/8" | 1/1/8" | 12" | 19.1/4" | 12.7/8" | 17.1/4" | 16 | 7/8" | 1.1/2" | |

| 14" | 21.3/4" | 14.9/64" | 19.1/2" | 16 | 1" | 1.1/4" | 4" | 21.3/4" | 14.9/64" | 19.1/2" | 16 | 1" | 1.5/8" | |

| 16" | 24" | 16.5/32" | 21.3/4" | 20 | 1" | 1.1/4" | 6" | 24" | 16.5/32" | 21.3/4" | 20 | 1" | 1.3/4" | |

| 18" | 26.1/2" | 18.3/16" | 24" | 20 | 1.1/8" | 1.3/8" | 18" | 26.1/2" | 18.3/16" | 24" | 20 | 1.1/8" | 1.7/8" | |

| 20" | 29" | 20.13/16" | 26.1/2" | 24 | 1.1/8" | 1.1/2" | 20" | 29" | 20.13/16" | 26.1/2" | 24 | 1.1/8" | 2" | |

| 24" | 33.1/2" | 24.1/4" | 30.3/4" | 24 | 1.1/4" | 1.5/8" | 24" | 33.1/2" | 24.1/4" | 30.3/4" | 24 | 1.1/4" | 2.1/4" | |

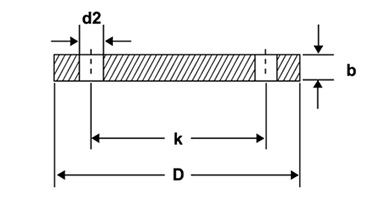

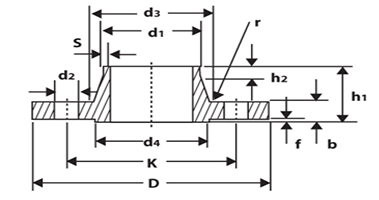

| DIN 2502 PN 16 (in mm) | ||||||||

| Nominal Pipe Size | Diameter of | Flange Dia | Flange I.D | Thk of Flanges | Dia of Bolt Cirlce | No. of | Dia of Bolt Holes | |

| DN | Pipe | D | D5 | B | K | holes | D2 | KG |

| 10 | 17.20 | 90 | 17.70 | 14 | 60 | 4 | 14 | 0.60 |

| 15 | 21.30 | 95 | 22.00 | 14 | 65 | 4 | 14 | 0.67 |

| 20 | 26.90 | 105 | 27.60 | 16 | 75 | 4 | 14 | 0.94 |

| 25 | 33.70 | 115 | 34.40 | 16 | 85 | 4 | 14 | 1.11 |

| 32 | 42.40 | 140 | 43.10 | 16 | 100 | 4 | 18 | 1.62 |

| 40 | 48.30 | 150 | 49.00 | 16 | 110 | 4 | 18 | 1.85 |

| 50 | 60.30 | 165 | 61.10 | 18 | 125 | 4 | 18 | 2.46 |

| 65 | 76.10 | 185 | 77.10 | 18 | 145 | 4 | 18 | 2.99 |

| 80 | 88.90 | 200 | 90.30 | 20 | 160 | 8 | 18 | 3.61 |

| 100 | 114.30 | 220 | 115.90 | 20 | 180 | 8 | 18 | 3.99 |

| 125 | 139.70 | 250 | 141.60 | 22 | 210 | 8 | 18 | 5.41 |

| 150 | 168.30 | 285 | 170.50 | 22 | 240 | 8 | 22 | 6.55 |

| 175 | 193.70 | 315 | 196.10 | 24 | 270 | 8 | 22 | 8.42 |

| 200 | 219.10 | 340 | 221.80 | 24 | 295 | 12 | 22 | 8.97 |

| 250 | 273.00 | 405 | 276.20 | 26 | 355 | 12 | 26 | 12.76 |

| 300 | 323.90 | 460 | 327.60 | 28 | 410 | 12 | 26 | 16.60 |

| 350 | 355.60 | 520 | 359.70 | 30 | 470 | 16 | 26 | 24.08 |

| 400 | 406.40 | 580 | 411.00 | 32 | 525 | 16 | 30 | 30.20 |

| 450 | 457.00 | 640 | 462.30 | 38 | 585 | 20 | 30 | 41.67 |

| 500 | 508.00 | 715 | 513.60 | 38 | 650 | 20 | 33 | 52.87 |

| 600 | 610.00 | 840 | 616.50 | 42 | 770 | 20 | 36 | 77.58 |

| 700 | 711.00 | 910 | 716.00 | 44 | 840 | 24 | 36 | 77.13 |

| 800 | 813.00 | 1025 | 818.00 | 50 | 950 | 24 | 39 | 106.35 |

| 900 | 914.00 | 1125 | 920.00 | 54 | 1050 | 28 | 39 | 125.39 |

| 1000 | 1016.00 | 1255 | 1022.00 | 60 | 1170 | 28 | 42 | 177.99 |

| DIN 2503 PN25 (in mm) | DIN 2503 PN40 (in mm) | |||||||||||||||||

| Nominal Pipe Size | Diameter of | Flange I.D | Flange Dia | Thk of Flange | Dia of Bolt Circle | No. of | Dia of Bolt Holes | Nominal Pipe Size | Diameter of | Flange I.D | Flange Dia | Thk of Flange | Dia of Bolt Cirlce | No. of | Dia of Bolt Holes | |||

| DN | Pipe | D5 | D | B | K | holes | D2 | KG | DN | Pipe | D5 | D | B | K | holes | D2 | KG | |

| 10 | 17.20 | 17.70 | 90 | 16 | 60 | 4 | 14 | 0.69 | 10 | 17.20 | 17.70 | 90 | 16 | 60 | 4 | 14 | 0.69 | |

| 15 | 21.30 | 22.00 | 95 | 16 | 65 | 4 | 14 | 0.77 | 15 | 21.30 | 22.00 | 95 | 16 | 65 | 4 | 14 | 0.77 | |

| 20 | 26.90 | 27.60 | 105 | 18 | 75 | 4 | 14 | 1.05 | 20 | 26.90 | 27.60 | 105 | 18 | 75 | 4 | 14 | 1.05 | |

| 25 | 33.70 | 34.40 | 115 | 18 | 85 | 4 | 14 | 1.25 | 25 | 33.70 | 34.40 | 115 | 18 | 85 | 4 | 14 | 1.25 | |

| 32 | 42.40 | 43.10 | 140 | 18 | 100 | 4 | 18 | 1.83 | 32 | 42.40 | 43.10 | 140 | 18 | 100 | 4 | 18 | 1.83 | |

| 40 | 48.30 | 49.00 | 150 | 18 | 110 | 4 | 18 | 2.09 | 40 | 48.30 | 49.00 | 150 | 18 | 110 | 4 | 18 | 2.09 | |

| 50 | 60.30 | 61.10 | 165 | 20 | 125 | 4 | 18 | 2.74 | 50 | 60.30 | 61.10 | 165 | 20 | 125 | 4 | 18 | 2.74 | |

| 65 | 76.10 | 77.10 | 185 | 22 | 145 | 8 | 18 | 3.48 | 65 | 76.10 | 77.10 | 185 | 22 | 145 | 8 | 18 | 3.48 | |

| 80 | 88.90 | 90.30 | 200 | 24 | 160 | 8 | 18 | 4.33 | 80 | 88.90 | 90.30 | 200 | 24 | 160 | 8 | 18 | 4.33 | |

| 100 | 114.30 | 115.90 | 235 | 24 | 190 | 8 | 22 | 5.61 | 100 | 114.30 | 115.90 | 235 | 24 | 190 | 8 | 22 | 5.61 | |

| 125 | 139.70 | 141.60 | 270 | 26 | 220 | 8 | 26 | 7.60 | 125 | 139.70 | 141.60 | 270 | 26 | 220 | 8 | 26 | 7.60 | |

| 150 | 168.30 | 170.50 | 300 | 28 | 250 | 8 | 26 | 9.58 | 150 | 168.30 | 170.50 | 300 | 28 | 250 | 8 | 26 | 9.58 | |

| 175 | 193.70 | 196.10 | 330 | 28 | 280 | 12 | 26 | 10.76 | 175 | 193.70 | 196.10 | 350 | 32 | 295 | 12 | 30 | 14.45 | |

| 200 | 219.10 | 221.80 | 360 | 30 | 310 | 12 | 26 | 13.37 | 200 | 219.10 | 221.80 | 375 | 34 | 320 | 12 | 30 | 16.90 | |

| 250 | 273.00 | 276.20 | 425 | 32 | 370 | 12 | 30 | 18.45 | 250 | 273.00 | 276.20 | 450 | 38 | 385 | 12 | 33 | 26.51 | |

| 300 | 323.90 | 327.60 | 485 | 34 | 430 | 16 | 30 | 23.79 | 300 | 323.90 | 327.60 | 515 | 42 | 450 | 16 | 33 | 36.38 | |

| 350 | 355.60 | 359.70 | 555 | 38 | 490 | 16 | 33 | 37.77 | 350 | 355.60 | 359.70 | 580 | 46 | 510 | 16 | 36 | 52.83 | |

| 400 | 406.40 | 411.00 | 620 | 40 | 550 | 16 | 36 | 45.41 | 400 | 406.40 | 411.00 | 660 | 50 | 585 | 16 | 39 | 74.71 | |

| 500 | 508.00 | 513.60 | 730 | 44 | 660 | 20 | 36 | 65.97 | 500 | 508.00 | 513.60 | 755 | 52 | 670 | 20 | 42 | 86.87 | |

| 600 | 610.00 | 616.50 | 845 | 50 | 770 | 20 | 39 | 93.57 | 600 | 610.00 | 616.50 | 890 | 54 | 795 | 20 | 48 | 121.84 | |

| 700 | 711.00 | 716.00 | 960 | 52 | 875 | 24 | 42 | 117.53 | 700 | 711.00 | 716.00 | 995 | 58 | 900 | 24 | 48 | 150.93 | |

| 800 | 813.00 | 818.00 | 1085 | 56 | 990 | 24 | 48 | 156.34 | 800 | 813.00 | 818.00 | 1140 | 64 | 1030 | 24 | 56 | 219.08 | |

| 900 | 914.00 | 920.00 | 1185 | 62 | 1090 | 28 | 48 | 188.57 | 900 | 914.00 | 920.00 | 1250 | 70 | 1140 | 28 | 56 | 271.16 | |

| 1000 | 1016.00 | 1022.00 | 1320 | 68 | 1210 | 28 | 56 | 255.79 | 1000 | 1016.00 | 1022.00 | 1360 | 78 | 1250 | 28 | 56 | 344.95 | |

| DIN 2527 PN6 (in mm) | DIN 2527 PN10 (in mm) | |||||||||||||

| Nominal Pipe Size | Flange Dia | Thk of Flange | Dia of Bolt Circle | No. of | Dia of Bolt Holes | Nominal Pipe Size | Flange Dia | Thk of Flange | Dia of Bolt Circle | No. of | Dia of Bolt Holes | |||

| DIN | D | B | K | holes | D2 | KG | DIN | D | B | K | holes | D2 | KG | |

| 10 | 75 | 12 | 50 | 4 | 11 | 0.38 | 10 | 90 | 14 | 60 | 4 | 14 | 0.63 | |

| 15 | 80 | 12 | 55 | 4 | 11 | 0.44 | 15 | 95 | 14 | 65 | 4 | 14 | 0.71 | |

| 20 | 90 | 14 | 65 | 4 | 11 | 0.66 | 20 | 105 | 16 | 75 | 4 | 14 | 1.01 | |

| 25 | 100 | 14 | 75 | 4 | 11 | 0.82 | 25 | 115 | 16 | 85 | 4 | 14 | 1.23 | |

| 32 | 120 | 14 | 90 | 4 | 14 | 1.18 | 32 | 140 | 16 | 100 | 4 | 18 | 1.81 | |

| 40 | 130 | 14 | 100 | 4 | 14 | 1.39 | 40 | 150 | 16 | 110 | 4 | 18 | 2.09 | |

| 50 | 140 | 14 | 110 | 4 | 14 | 1.62 | 50 | 165 | 18 | 125 | 4 | 18 | 2.88 | |

| 65 | 160 | 14 | 130 | 4 | 14 | 2.14 | 65 | 185 | 18 | 145 | 4 | 18 | 3.65 | |

| 80 | 190 | 16 | 150 | 4 | 48 | 3.43 | 80 | 200 | 20 | 160 | 4 | 18 | 4.61 | |

| 100 | 210 | 16 | 170 | 4 | 18 | 4.22 | 100 | 220 | 20 | 180 | 4 | 18 | 5.65 | |

| 125 | 240 | 18 | 200 | 8 | 18 | 6.10 | 125 | 250 | 22 | 210 | 8 | 18 | 8.13 | |

| 150 | 265 | 18 | 225 | 8 | 18 | 7.51 | 150 | 285 | 22 | 240 | 8 | 22 | 10.49 | |

| 175 | 295 | 20 | 255 | 8 | 18 | 10.41 | 175 | 315 | 24 | 270 | 8 | 22 | 14.11 | |

| 200 | 320 | 20 | 280 | 8 | 18 | 12.31 | 200 | 340 | 24 | 295 | 8 | 22 | 16.53 | |

| 250 | 375 | 22 | 335 | 12 | 18 | 18.55 | 250 | 395 | 26 | 350 | 12 | 22 | 24.08 | |

| 300 | 440 | 22 | 395 | 12 | 22 | 25.47 | 300 | 445 | 26 | 400 | 12 | 22 | 30.81 | |

| 350 | 490 | 22 | 445 | 12 | 22 | 31.78 | 350 | 505 | 26 | 460 | 12 | 22 | 39.64 | |

| 400 | 540 | 22 | 495 | 16 | 22 | 38.50 | 400 | 565 | 26 | 515 | 16 | 26 | 49.44 | |

| 500 | 645 | 24 | 600 | 20 | 22 | 60.13 | 500 | 670 | 28 | 620 | 20 | 26 | 75.16 | |

| 600 | 755 | 28 | 705 | 20 | 26 | 96.07 | 600 | 780 | 30 | 725 | 20 | 30 | 109.20 | |

| 700 | 860 | 30 | 810 | 24 | 26 | 133.80 | 700 | 895 | 32 | 840 | 24 | 30 | 153.77 | |

| 800 | 975 | 32 | 920 | 24 | 30 | 183.29 | 800 | 1015 | 36 | 950 | 24 | 33 | 222.86 | |

| 900 | 1075 | 36 | 1020 | 24 | 30 | 251.70 | 900 | 1115 | 40 | 1050 | 24 | 33 | 299.08 | |

| 1000 | 1175 | 42 | 1120 | 28 | 30 | 350.98 | 1000 | 1230 | 46 | 1160 | 28 | 36 | 418.78 | |

| DIN 2527 PN16 (in mm) | DIN 2527 PN25 (in mm) | |||||||||||||

| Nominal Pipe Size | Flange Dia | Thk of Flange | Dia of Bolt Circle | No. of | Dia of Bolt Holes | Nominal Pipe Size | Flange Dia | Thk of Flange | Dia of Bolt Circle | No. of | Dia of Bolt Holes | |||

| DIN | D | B | K | holes | D2 | KG | DIN | D | B | K | holes | D2 | KG | |

| 10 | 90 | 14 | 60 | 4 | 14 | 0.63 | 90 | 90 | 16 | 60 | 4 | 14 | 0.72 | |

| 15 | 95 | 14 | 65 | 4 | 14 | 0.71 | 95 | 95 | 16 | 65 | 4 | 14 | 0.81 | |

| 20 | 105 | 16 | 75 | 4 | 14 | 1.01 | 105 | 105 | 18 | 75 | 4 | 14 | 1.14 | |

| 25 | 115 | 16 | 85 | 4 | 14 | 1.23 | 115 | 115 | 18 | 85 | 4 | 14 | 1.38 | |

| 32 | 140 | 16 | 100 | 4 | 18 | 1.81 | 140 | 140 | 18 | 100 | 4 | 18 | 2.03 | |

| 40 | 150 | 16 | 110 | 4 | 18 | 2.09 | 150 | 150 | 18 | 110 | 4 | 18 | 2.35 | |

| 50 | 165 | 18 | 125 | 4 | 18 | 2.88 | 165 | 165 | 20 | 125 | 4 | 18 | 3.20 | |

| 65 | 185 | 18 | 145 | 4 | 18 | 3.65 | 185 | 185 | 22 | 145 | 4 | 18 | 4.29 | |

| 80 | 200 | 20 | 160 | 8 | 18 | 4.61 | 200 | 200 | 24 | 160 | 8 | 18 | 5.54 | |

| 100 | 220 | 20 | 180 | 8 | 18 | 5.65 | 235 | 220 | 24 | 190 | 8 | 22 | 7.60 | |

| 125 | 250 | 22 | 210 | 8 | 18 | 8.13 | 270 | 250 | 26 | 220 | 8 | 26 | 10.82 | |

| 150 | 285 | 22 | 240 | 8 | 22 | 10.49 | 300 | 285 | 28 | 250 | 8 | 26 | 14.60 | |

| 175 | 315 | 24 | 270 | 8 | 22 | 14.11 | 330 | 315 | 28 | 280 | 8 | 26 | 17.40 | |

| 200 | 340 | 24 | 295 | 12 | 22 | 16.26 | 360 | 340 | 30 | 310 | 12 | 26 | 22.47 | |

| 250 | 405 | 26 | 355 | 12 | 26 | 24.99 | 425 | 405 | 32 | 370 | 12 | 30 | 33.51 | |

| 300 | 460 | 28 | 410 | 12 | 26 | 35.13 | 485 | 460 | 34 | 430 | 12 | 30 | 46.29 | |

| 350 | 520 | 30 | 470 | 16 | 26 | 48.01 | 555 | 520 | 38 | 490 | 16 | 33 | 68.08 | |

| 400 | 580 | 32 | 525 | 16 | 30 | 83.53 | 620 | 580 | 40 | 550 | 16 | 36 | 89.59 | |

| 500 | 715 | 36 | 650 | 20 | 33 | 108.63 | 730 | 715 | 45 | 660 | 20 | 36 | 140.66 | |

| 600 | 780 | 38 | 770 | 20 | 36 | 136.47 | 845 | 780 | 48 | 770 | 20 | 39 | 202.30 | |

| 700 | 895 | 40 | 840 | 24 | 36 | 189.87 | 960 | 895 | 50 | 875 | 24 | 42 | 271.05 | |

| 800 | 1015 | 44 | 950 | 24 | 39 | 269.57 | 1085 | 1015 | 54 | 990 | 24 | 48 | 373.52 | |

| 900 | 1115 | 48 | 1050 | 28 | 39 | 355.31 | 1185 | 1115 | 58 | 1090 | 28 | 48 | 479.07 | |

| 1000 | 1230 | 52 | 1170 | 28 | 42 | 469.20 | 1320 | 1230 | 62 | 1210 | 28 | 56 | 632.47 | |

| DIN 2527 PN40 (in mm) | DIN 2527 PN64 (in mm) | |||||||||||||

| Nominal Pipe Size | Flanges Dia | Thk of Flange | Dia of Bolt Circle | No. of | Dia of Bolt Holes | Nominal Pipe Size | Flanges Dia | Thk of Flange | Dia of Bolt Circle | No. of | Dia of Bolt Holes | |||

| DIN | D | B | K | holes | D2 | KG | DIN | D | B | K | holes | D2 | KG | |

| 10 | 90 | 16 | 60 | 4 | 14 | 0.72 | 10 | 90 | 20 | 70 | 4 | 14 | 1.04 | |

| 15 | 95 | 16 | 65 | 4 | 14 | 0.81 | 15 | 95 | 20 | 75 | 4 | 14 | 1.16 | |

| 20 | 105 | 18 | 75 | 4 | 14 | 1.14 | 20 | 105 | 24 | 100 | 4 | 18 | 2.54 | |

| 25 | 115 | 18 | 85 | 4 | 14 | 1.38 | 25 | 115 | 24 | 110 | 4 | 22 | 3.07 | |

| 32 | 140 | 18 | 100 | 4 | 18 | 2.03 | 32 | 140 | 26 | 125 | 4 | 22 | 3.97 | |

| 40 | 150 | 18 | 110 | 4 | 18 | 2.35 | 40 | 150 | 26 | 135 | 4 | 22 | 4.51 | |

| 50 | 165 | 20 | 125 | 4 | 18 | 3.20 | 50 | 165 | 26 | 160 | 4 | 22 | 5.69 | |

| 65 | 185 | 22 | 145 | 8 | 18 | 4.29 | 65 | 185 | 28 | 170 | 8 | 22 | 6.88 | |

| 80 | 200 | 24 | 160 | 8 | 18 | 5.54 | 80 | 200 | 30 | 200 | 8 | 26 | 9.99 | |

| 100 | 235 | 24 | 190 | 8 | 22 | 7.60 | 100 | 235 | 34 | 240 | 8 | 30 | 15.91 | |

| 125 | 270 | 26 | 220 | 8 | 26 | 10.82 | 125 | 270 | 36 | 280 | 8 | 33 | 23.32 | |

| 150 | 300 | 28 | 250 | 8 | 26 | 14.60 | 150 | 300 | 40 | 310 | 8 | 33 | 30.35 | |

| 175 | 350 | 32 | 295 | 12 | 30 | 22.04 | 175 | 350 | 42 | 345 | 12 | 36 | 39.17 | |

| 200 | 375 | 34 | 320 | 12 | 30 | 27.21 | 200 | 375 | 46 | 400 | 12 | 38 | 56.64 | |

| 250 | 450 | 38 | 385 | 12 | 33 | 44.38 | 250 | 450 | 52 | 460 | 12 | 36 | 81.14 | |

| 300 | 515 | 42 | 450 | 16 | 33 | 64.17 | 300 | 515 | 56 | 525 | 16 | 39 | 112.95 | |

| 350 | 580 | 46 | 510 | 16 | 36 | 89.52 | 350 | 580 | 60 | 585 | 16 | 42 | 152.30 | |

| 400 | 660 | 50 | 585 | 16 | 39 | 126.76 | 400 | 660 | - | - | 16 | - | - | |

| 500 | 755 | 56 | 670 | 20 | 42 | 184.63 | 500 | 755 | - | - | 20 | - | - | |

| 600 | 890 | 62 | 795 | 20 | 48 | 285.17 | 600 | 890 | - | - | 20 | - | - | |

| 700 | 995 | 64 | 900 | 24 | 48 | 368.83 | 700 | 995 | - | - | 24 | - | - | |

| 800 | 1140 | 70 | 1030 | 24 | 56 | 528.39 | 800 | 1140 | - | - | 24 | - | - | |

| 900 | 1250 | 76 | 1140 | 28 | 56 | 690.99 | 900 | 1250 | - | - | 28 | - | - | |

| 1000 | 1360 | 84 | 1250 | 28 | 56 | 912.42 | 1000 | 1360 | - | - | 28 | - | - | |

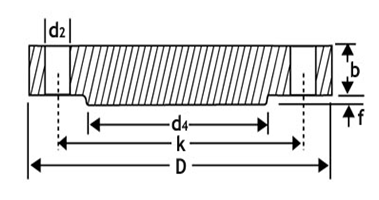

| DIN 2527 PN100 (in mm) | ||||||||

| Nominal Pipe Size | Flange Dia | Thk of Flange | Dia of Bolt Circle | Dia of R/F | Thk of R/F | No. of | Dia of Bolt Holes | |

| DN | D | B | K | D4 | F | Holes | D2 | KG |

| 10 | 100 | 20 | 70 | 40 | 2 | 4 | 14 | 1.04 |

| 15 | 105 | 20 | 75 | 45 | 2 | 4 | 14 | 1.16 |

| 25 | 140 | 24 | 100 | 68 | 2 | 4 | 18 | 2.54 |

| 32 | 155 | 24 | 110 | 78 | 2 | 4 | 22 | 3.07 |

| 40 | 170 | 26 | 125 | 88 | 3 | 4 | 22 | 3.97 |

| 50 | 195 | 28 | 145 | 102 | 3 | 4 | 26 | 5.64 |

| 65 | 220 | 30 | 170 | 122 | 3 | 8 | 26 | 7.43 |

| 80 | 230 | 32 | 180 | 138 | 3 | 8 | 26 | 8.84 |

| 100 | 265 | 36 | 210 | 162 | 3 | 8 | 30 | 13.31 |

| 125 | 315 | 40 | 250 | 188 | 3 | 8 | 33 | 21.30 |

| 150 | 355 | 44 | 290 | 218 | 3 | 12 | 33 | 29.43 |

| 175 | 385 | 48 | 320 | 260 | 3 | 12 | 33 | 38.75 |

| 200 | 430 | 52 | 360 | 285 | 3 | 12 | 36 | 52.66 |

| 250 | 505 | 60 | 430 | 345 | 3 | 12 | 39 | 85.41 |

| 300 | 585 | 68 | 500 | 410 | 4 | 16 | 42 | 128.05 |

| 350 | 655 | 74 | 560 | 465 | 4 | 16 | 48 | 174.53 |

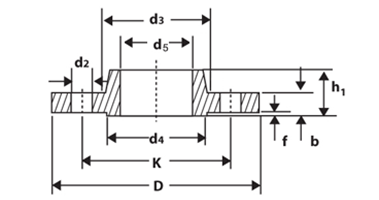

| DIN 2565 PN 6 (in mm) | |||||||||||

| Nominal Pipe Size | Flange Dia | Flange I.D | Thk of Flange | Dia of Bolt Cirlce | Length Through Hub | Dia of Hub | Dia of R/F | Thk of R/F | No. of | Dia of Bolt Holes | |

| DN | D | D5 | B | K | H1 | D3 | D4 | F | holes | D2 | KG |

| 6 | 65 | 11.7 | 10 | 40 | 18 | 18 | 25 | 2 | 4 | 11.5 | 0.19 |

| 8 | 70 | 15.0 | 10 | 45 | 18 | 22 | 30 | 2 | 4 | 11.5 | 0.23 |

| 10 | 75 | 17.70 | 12 | 50 | 20 | 25 | 35 | 2 | 4 | 11.5 | 0.32 |

| 15 | 80 | 22.00 | 12 | 55 | 20 | 30 | 40 | 2 | 4 | 11.5 | 0.37 |

| 20 | 90 | 27.60 | 14 | 65 | 24 | 40 | 50 | 2 | 4 | 11.5 | 0.58 |

| 25 | 100 | 34.40 | 14 | 75 | 24 | 50 | 60 | 2 | 4 | 11.5 | 0.73 |

| 32 | 120 | 43.10 | 14 | 90 | 26 | 60 | 70 | 2 | 4 | 14.0 | 1.05 |

| 40 | 130 | 49.00 | 14 | 100 | 26 | 70 | 80 | 3 | 4 | 14.0 | 1.20 |

| 50 | 140 | 61.10 | 14 | 110 | 28 | 80 | 90 | 3 | 4 | 14.0 | 1.54 |

| 65 | 160 | 77.10 | 14 | 130 | 32 | 100 | 110 | 3 | 4 | 14.0 | 1.87 |

| 80 | 190 | 90.30 | 16 | 150 | 34 | 110 | 128 | 3 | 4 | 18.0 | 2.78 |

| 100 | 210 | 115.90 | 16 | 170 | 38 | 130 | 148 | 3 | 4 | 18.0 | 3.07 |

| 150 | 240 | 170.50 | 18 | 200 | 40 | 160 | 178 | 3 | 8 | 18.0 | 4.33 |

| 200 | 285 | 221.80 | 18 | 225 | 44 | 185 | 202 | 3 | 8 | 18.0 | 4.81 |

| DIN 2566 PN 16 (in mm) | |||||||||||

| Nominal Pipe Size | Flange Dia | Flange I.D | Thk of Flange | Dia of Bolt Cirlce | Length Through Hub | Dia of Hub | Dia of R/F | Thk of R/F | No. of | Dia of Bolt Holes | |

| DN | D | D5 | B | K | H1 | D3 | D4 | F | holes | D2 | KG |

| 6 | 75 | 11.7 | 12 | 50 | 18 | 20 | 32 | 2 | 4 | 11 | 0.33 |

| 8 | 80 | 15.0 | 12 | 55 | 18 | 25 | 38 | 2 | 4 | 11 | 0.39 |

| 10 | 90 | 17.70 | 14 | 60 | 20 | 30 | 40 | 2 | 4 | 14 | 0.56 |

| 15 | 95 | 22.00 | 14 | 65 | 20 | 35 | 45 | 2 | 4 | 14 | 0.62 |

| 20 | 105 | 27.60 | 16 | 75 | 24 | 45 | 58 | 2 | 4 | 14 | 0.92 |

| 25 | 115 | 34.40 | 16 | 85 | 24 | 52 | 68 | 2 | 4 | 14 | 1.10 |

| 32 | 140 | 43.10 | 16 | 100 | 26 | 60 | 78 | 2 | 4 | 18 | 1.59 |

| 40 | 150 | 49.00 | 16 | 110 | 26 | 70 | 88 | 3 | 4 | 18 | 1.77 |

| 50 | 165 | 61.10 | 18 | 125 | 28 | 85 | 102 | 3 | 4 | 18 | 2.41 |

| 65 | 185 | 77.10 | 18 | 145 | 32 | 105 | 122 | 3 | 4 | 18 | 3.13 |

| 80 | 200 | 90.30 | 20 | 160 | 34 | 118 | 138 | 3 | 4 | 18 | 3.95 |

| 100 | 220 | 115.90 | 20 | 180 | 38 | 140 | 158 | 3 | 8 | 18 | 4.38 |

| 125 | 250 | 143.80 | 22 | 210 | 40 | 168 | 188 | 3 | 8 | 18 | 5.99 |

| 150 | 285 | 170.50 | 22 | 240 | 44 | 196 | 212 | 3 | 8 | 22 | 7.42 |

| DIN 2573 PN 6 (in mm) | ||||||||

| Nominal Pipe Size | Diameter of | Flange I.D | Flange Dia | Thk of Flange | Dia of Bolt Circle | No. of | Dia of Bolt Holes | |

| DN | Pipe | D5 | D | B | K | holes | D2 | KG |

| 10 | 17.20 | 17.70 | 75 | 12 | 50 | 4 | 11 | 0.36 |

| 15 | 21.30 | 22.00 | 80 | 12 | 55 | 4 | 11 | 0.40 |

| 20 | 26.90 | 27.60 | 90 | 14 | 65 | 4 | 11 | 0.59 |

| 25 | 33.70 | 34.40 | 100 | 14 | 75 | 4 | 11 | 0.72 |

| 32 | 42.40 | 43.10 | 120 | 16 | 90 | 4 | 14 | 1.16 |

| 40 | 48.30 | 49.00 | 130 | 16 | 100 | 4 | 14 | 1.35 |

| 50 | 60.30 | 61.10 | 140 | 16 | 110 | 4 | 14 | 1.49 |

| 65 | 76.10 | 77.10 | 160 | 16 | 130 | 4 | 14 | 1.86 |

| 80 | 88.90 | 90.30 | 190 | 18 | 150 | 4 | 14 | 2.96 |

| 100 | 114.30 | 115.90 | 210 | 18 | 170 | 4 | 18 | 3.26 |

| 125 | 139.70 | 141.60 | 240 | 20 | 200 | 8 | 18 | 4.31 |

| 150 | 168.20 | 170.50 | 265 | 20 | 225 | 8 | 18 | 4.76 |

| 200 | 219.10 | 221.80 | 320 | 22 | 280 | 8 | 18 | 6.87 |

| 250 | 273.00 | 276.20 | 325 | 24 | 335 | 12 | 18 | 8.94 |

| 300 | 323.90 | 327.60 | 440 | 24 | 395 | 12 | 22 | 11.91 |

| 350 | 355.60 | 359.70 | 480 | 26 | 445 | 12 | 22 | 16.52 |

| 400 | 406.40 | 411.00 | 540 | 28 | 495 | 16 | 22 | 18.84 |

| 450 | 457.00 | 462.30 | 595 | 30 | 550 | 16 | 22 | 24.52 |

| 500 | 508.00 | 513.60 | 645 | 30 | 600 | 20 | 22 | 26.37 |

| DIN 2576 PN 10 (in mm) | ||||||||

| Nominal Pipe Size | Diameter of | Flange I.D | Flange Dia | Thk of Flange | Dia of Bolt Circle | No. of | Dia of Bolt Holes | |

| DN | Pipe | D5 | D | B | K | holes | D2 | KG |

| 10 | 17.20 | 17.70 | 90 | 14 | 60 | 4 | 14 | 0.60 |

| 15 | 21.30 | 22.00 | 95 | 14 | 65 | 4 | 14 | 0.67 |

| 20 | 26.90 | 27.60 | 105 | 16 | 75 | 4 | 14 | 0.94 |

| 25 | 33.70 | 34.40 | 115 | 16 | 85 | 4 | 14 | 1.11 |

| 32 | 42.40 | 43.10 | 140 | 16 | 100 | 4 | 18 | 1.62 |

| 40 | 48.30 | 49.00 | 150 | 16 | 110 | 4 | 18 | 1.85 |

| 50 | 60.30 | 61.10 | 165 | 18 | 125 | 4 | 18 | 2.46 |

| 65 | 76.10 | 77.10 | 185 | 18 | 145 | 4 | 18 | 2.99 |

| 80 | 88.90 | 90.30 | 200 | 20 | 160 | 8 | 18 | 3.61 |

| 100 | 114.30 | 115.90 | 220 | 20 | 180 | 8 | 18 | 3.99 |

| 125 | 139.70 | 141.60 | 250 | 22 | 210 | 8 | 18 | 5.41 |

| 150 | 168.30 | 170.50 | 285 | 22 | 240 | 8 | 22 | 6.55 |

| 175 | 193.70 | 196.10 | 315 | 24 | 270 | 8 | 22 | 8.42 |

| 200 | 219.10 | 221.80 | 340 | 24 | 295 | 8 | 22 | 9.28 |

| 250 | 273.00 | 276.20 | 395 | 26 | 350 | 12 | 22 | 11.85 |

| 300 | 323.90 | 327.60 | 445 | 26 | 400 | 12 | 22 | 13.61 |

| 350 | 355.60 | 359.70 | 505 | 28 | 460 | 16 | 22 | 20.35 |

| 400 | 406.40 | 411.00 | 565 | 32 | 515 | 18 | 26 | 27.52 |

| 450 | 457.00 | 462.30 | 615 | 38 | 565 | 20 | 26 | 35.11 |

| 500 | 508.00 | 613.60 | 670 | 38 | 620 | 20 | 26 | 40.20 |

| 600 | 610.00 | 615.50 | 780 | 40 | 725 | 20 | 26 | 51.87 |

| DIN 2627 PN 400 (in mm) | ||||||||||||||

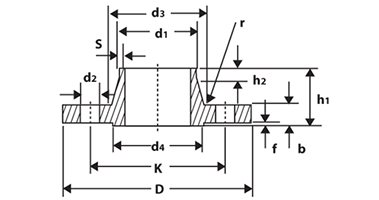

| Nominal Pipe Size | Diameter at weld Bevel | Flange Dia | Thk of Flange | Dia of Bolt Circle | Length Through Hub | Dia of Hub | Wall Thk | Radius of Hub | Straight Portion | Dia of R/F | Thk of R/F | No. of | Dia of Bolt Holes | |

| DN | D1 | D | B | K | H1 | D3 | S | R | H2 | D4 | F | holes | D2 | KG |

| 10 | 17.20 | 125 | 28 | 85 | 65 | 48 | 3.60 | 4 | 8 | 40 | 2 | 4 | 18 | 2.50 |

| 15 | 26.90 | 145 | 30 | 100 | 68 | 56 | 5.00 | 4 | 8 | 45 | 2 | 4 | 22 | 3.57 |

| 25 | 42.40 | 180 | 38 | 130 | 90 | 82 | 7.10 | 4 | 10 | 68 | 2 | 4 | 26 | 7.35 |

| 40 | 60.30 | 220 | 48 | 165 | 110 | 106 | 10.00 | 6 | 12 | 88 | 3 | 4 | 30 | 13.93 |

| 50 | 76.10 | 235 | 52 | 180 | 120 | 120 | 12.50 | 6 | 15 | 102 | 3 | 8 | 30 | 16.50 |

| 65 | 101.60 | 290 | 64 | 225 | 135 | 158 | 16.00 | 6 | 18 | 122 | 3 | 8 | 33 | 31.33 |

| 80 | 114.30 | 305 | 68 | 240 | 150 | 174 | 17.50 | 8 | 20 | 138 | 3 | 8 | 33 | 37.99 |

| 100 | 139.70 | 370 | 80 | 295 | 175 | 215 | 22.20 | 8 | 25 | 162 | 3 | 8 | 39 | 66.77 |

| 125 | 193.70 | 415 | 92 | 340 | 200 | 258 | 30.00 | 8 | 30 | 188 | 3 | 12 | 39 | 94.73 |

| 150 | 219.10 | 475 | 105 | 390 | 225 | 302 | 35.00 | 10 | 35 | 218 | 3 | 12 | 42 | 144.85 |

| 200 | 273.00 | 585 | 130 | 490 | 280 | 388 | 40.00 | 10 | 40 | 285 | 3 | 16 | 48 | 269.50 |

| DIN 2628 PN 250 (in mm) | ||||||||||||||

| Nominal Pipe Size | Diameter at weld Bevel | Flange Dia | Thk of Flange | Dia of Bolt Circle | Length Through Hub | Dia of Hub | Wall Thk | Radius of Hub | Straight Portion | Dia of R/F | Thk of R/F | No. of | Dia of Bolt Holes | |

| DN | D1 | D | B | K | H1 | D3 | S | R | H2 | D4 | F | holes | D2 | KG |

| 10 | 17.2 | 125 | 24 | 85 | 58 | 44 | 2.6 | 4 | 6 | 40 | 2 | 4 | 18 | 2.09 |

| 15 | 21.3 | 130 | 26 | 90 | 60 | 48 | 2.6 | 4 | 6 | 45 | 2 | 4 | 18 | 2.47 |

| 25 | 33.7 | 150 | 28 | 105 | 65 | 60 | 3.6 | 4 | 8 | 68 | 2 | 4 | 22 | 3.53 |

| 40 | 48.3 | 185 | 34 | 135 | 80 | 84 | 5 | 6 | 10 | 88 | 3 | 4 | 26 | 6.58 |

| 50 | 60.3 | 200 | 38 | 150 | 85 | 95 | 6.3 | 6 | 10 | 102 | 3 | 8 | 26 | 8.09 |

| 65 | 76.1 | 230 | 42 | 180 | 95 | 124 | 8 | 6 | 12 | 122 | 3 | 8 | 26 | 12.59 |

| 80 | 101.6 | 255 | 46 | 200 | 102 | 136 | 11 | 8 | 12 | 138 | 3 | 8 | 30 | 16.32 |

| 100 | 127 | 300 | 54 | 235 | 120 | 164 | 14.2 | 8 | 14 | 162 | 3 | 8 | 33 | 27.07 |

| 125 | 152.4 | 340 | 60 | 275 | 140 | 200 | 16 | 8 | 16 | 188 | 3 | 12 | 33 | 38.79 |

| 150 | 177.8 | 390 | 68 | 320 | 160 | 240 | 17.5 | 10 | 18 | 218 | 3 | 12 | 36 | 59.05 |

| 200 | 244.5 | 485 | 82 | 400 | 190 | 305 | 25 | 10 | 25 | 285 | 3 | 12 | 42 | 109.45 |

| 250 | 298.5 | 585 | 100 | 490 | 215 | 385 | 32 | 12 | 30 | 345 | 3 | 16 | 48 | 189.94 |

| DIN 2629 P N 320 (in mm) | ||||||||||||||

| Nominal Pipe Size | Diameter at weld Bevel | Flange Dia | Thk of Flange | Dia of Bolt Circle | Length Through Hub | Dia of Hub | Wall Thk | Radius of Hub | Straight Portion | Dia of R/F | Thk of R/F | No. of | Dia of Bolt Holes | |

| DN | D1 | D | B | K | H1 | D3 | S | R | H2 | D4 | F | holes | D2 | KG |

| 10 | 17.2 | 125 | 24 | 85 | 58 | 44 | 2.6 | 4 | 6 | 40 | 2 | 4 | 18 | 2.09 |

| 15 | 21.3 | 130 | 26 | 90 | 60 | 48 | 3.2 | 4 | 6 | 45 | 2 | 4 | 18 | 2.49 |

| 25 | 33.7 | 160 | 34 | 115 | 78 | 68 | 5 | 4 | 8 | 68 | 2 | 4 | 22 | 5.11 |

| 40 | 48.3 | 195 | 38 | 145 | 88 | 92 | 6.3 | 6 | 10 | 88 | 3 | 4 | 26 | 8.47 |

| 50 | 63.5 | 210 | 42 | 160 | 100 | 106 | 8 | 6 | 10 | 102 | 3 | 8 | 26 | 10.52 |

| 65 | 88.9 | 255 | 51 | 200 | 120 | 138 | 11 | 6 | 12 | 122 | 3 | 8 | 30 | 19.26 |

| 80 | 101.6 | 275 | 55 | 220 | 130 | 156 | 12.5 | 8 | 14 | 138 | 3 | 8 | 30 | 24.81 |

| 100 | 133 | 335 | 65 | 265 | 145 | 186 | 16 | 8 | 16 | 162 | 3 | 8 | 36 | 42.18 |

| 125 | 168.3 | 380 | 75 | 310 | 175 | 230 | 20 | 8 | 20 | 188 | 3 | 12 | 36 | 63.30 |

| 150 | 193.7 | 425 | 84 | 350 | 195 | 265 | 25 | 10 | 25 | 218 | 3 | 12 | 36 | 91.04 |

| 175 | 219.1 | 485 | 95 | 400 | 215 | 308 | 28 | 10 | 28 | 260 | 3 | 12 | 42 | 135.46 |

| 200 | 244.5 | 525 | 103 | 440 | 235 | 345 | 30 | 10 | 30 | 285 | 3 | 16 | 42 | 170.94 |

| 250 | 323.9 | 640 | 125 | 540 | 300 | 428 | 40 | 12 | 40 | 345 | 3 | 16 | 52 | 311.99 |

| DIN 2630 P N 2.5 (in mm) | ||||||||||||||

| Nominal Pipe Size | Diameter at weld Bevel | Flange Dia | Thk of Flange | Dia of Bolt Circle | Length Through Hub | Dia of Hub | Wall Thk | Radius of Hub | Straight Portion | Dia of R/F | Thk of R/F | No. of | Dia of Bolt Holes | |

| DN | D1 | D | B | K | H1 | D3 | S | R | H2 | D4 | F | holes | D2 | KG |

| 10 | 17.20 | 75 | 12 | 50 | 28 | 26 | 1.8 | 4 | 6 | 35 | 2 | 4 | 11 | 0.34 |

| 15 | 21.30 | 80 | 12 | 55 | 30 | 30 | 2 | 4 | 6 | 40 | 2 | 4 | 11 | 0.46 |

| 20 | 26.90 | 90 | 14 | 65 | 32 | 38 | 2.3 | 4 | 6 | 50 | 2 | 4 | 11 | 0.60 |

| 25 | 33.70 | 100 | 14 | 75 | 35 | 42 | 2.6 | 4 | 6 | 60 | 2 | 4 | 11 | 0.78 |

| 32 | 42.40 | 120 | 14 | 90 | 35 | 55 | 2.6 | 6 | 6 | 70 | 2 | 4 | 14 | 1.06 |

| 40 | 48.30 | 130 | 14 | 100 | 38 | 62 | 2.6 | 6 | 7 | 80 | 3 | 4 | 14 | 1.20 |

| 50 | 60.30 | 140 | 14 | 110 | 38 | 74 | 2.9 | 6 | 8 | 90 | 3 | 4 | 14 | 1.36 |

| 65 | 76.10 | 160 | 14 | 130 | 38 | 88 | 2.9 | 6 | 9 | 110 | 3 | 4 | 14 | 1.60 |

| 80 | 88.90 | 190 | 16 | 150 | 42 | 102 | 3.2 | 8 | 10 | 128 | 3 | 4 | 18 | 2.72 |

| 100 | 114.30 | 210 | 16 | 170 | 45 | 130 | 3.6 | 8 | 10 | 148 | 3 | 4 | 18 | 3.22 |

| 125 | 139.70 | 240 | 18 | 200 | 48 | 155 | 4 | 8 | 10 | 178 | 3 | 8 | 18 | 4.42 |

| 150 | 168.3 | 265 | 18 | 225 | 48 | 184 | 4.5 | 10 | 12 | 202 | 3 | 8 | 18 | 5.04 |

| 200 | 219.10 | 320 | 20 | 280 | 55 | 236 | 5.9 | 10 | 15 | 258 | 3 | 8 | 18 | 7.95 |

| 250 | 273.00 | 375 | 22 | 335 | 60 | 290 | 6.3 | 12 | 16 | 312 | 3 | 12 | 18 | 10.57 |

| 300 | 323.90 | 440 | 22 | 395 | 62 | 342 | 7.1 | 12 | 15 | 365 | 4 | 12 | 22 | 14.26 |

| 350 | 355.60 | 490 | 22 | 445 | 62 | 385 | 7.1 | 12 | 15 | 415 | 4 | 12 | 22 | 18.56 |

| 400 | 406.40 | 540 | 22 | 495 | 65 | 438 | 7.1 | 12 | 15 | 465 | 4 | 16 | 22 | 21.25 |

| 500 | 506.00 | 645 | 24 | 600 | 68 | 538 | 7.1 | 12 | 15 | 570 | 4 | 20 | 22 | 23.57 |

| 600 | 610.00 | 755 | 24 | 705 | 70 | 640 | 7.1 | 12 | 16 | 670 | 5 | 20 | 26 | 34.50 |

| 700 | 711.00 | 660 | 24 | 810 | 70 | 740 | 7.1 | 12 | 16 | 775 | 5 | 24 | 26 | 40.00 |

| 800 | 813.00 | 975 | 24 | 920 | 70 | 842 | 7.1 | 12 | 16 | 880 | 5 | 24 | 30 | 48.18 |

| 900 | 914.00 | 1075 | 26 | 1020 | 70 | 942 | 7.1 | 12 | 16 | 980 | 5 | 24 | 30 | 58.10 |

| 1000 | 1016.00 | 1175 | 26 | 1120 | 70 | 1045 | 7.1 | 16 | 16 | 1080 | 5 | 25 | 30 | 63.41 |

| 1200 | 1220.00 | 1375 | 26 | 1320 | 70 | 1245 | 7 | 16 | 16 | 1280 | 5 | 32 | 30 | 72.82 |

| 1400 | 1420.00 | 1575 | 26 | 1520 | 70 | 1445 | 7 | 16 | 16 | 1480 | 5 | 36 | 30 | 84.50 |

| 1600 | 1620.00 | 1790 | 26 | 1730 | 80 | 1645 | 8 | 16 | 20 | 1680 | 5 | 40 | 30 | 111.57 |

| 1800 | 1820.00 | 1990 | 26 | 1930 | 80 | 1845 | 9 | 16 | 20 | 1890 | 5 | 44 | 30 | 128.41 |

| 2000 | 2020.00 | 2190 | 26 | 2130 | 80 | 2045 | 10 | 18 | 22 | 2090 | 5 | 48 | 30 | 145.00 |

| 2200 | 2220.00 | 2405 | 28 | 2340 | 90 | 2248 | 10 | 18 | 25 | 2295 | 6 | 52 | 33 | 184.10 |

| 2400 | 2420.00 | 2605 | 28 | 2540 | 90 | 2448 | 10 | 18 | 25 | 2495 | 6 | 56 | 32 | 200.47 |

| 2600 | 2620.00 | 2805 | 28 | 2740 | 90 | 2648 | 10 | 18 | 25 | 2695 | 6 | 60 | 33 | 216.00 |

| 2800 | 2820.00 | 3030 | 30 | 2960 | 90 | 2848 | 10 | 18 | 25 | 2910 | 6 | 64 | 36 | 268.05 |

| 3000 | 3020.00 | 3230 | 30 | 3160 | 90 | 3050 | 10 | 18 | 25 | 3110 | 6 | 66 | 36 | 285.00 |

| 3200 | 3220.00 | 3430 | 30 | 3350 | 90 | 3250 | 10 | 20 | 25 | 3310 | 6 | 72 | 36 | 306.75 |

| 3400 | 3420.00 | 3630 | 32 | 3560 | 95 | 3450 | 10 | 20 | 28 | 3510 | 6 | 76 | 36 | 346.71 |

| 3600 | 3620.00 | 3340 | 32 | 3770 | 100 | 3652 | 10 | 20 | 28 | 3720 | 6 | 80 | 36 | 305.71 |

| 3800 | 3820.00 | 4045 | 34 | 3970 | 100 | 3852 | 10 | 20 | 28 | 3920 | 6 | 80 | - | - |

| 4000 | 4020.00 | 4245 | 34 | 4170 | 100 | 4052 | 10 | 20 | 28 | 4120 | 6 | 84 | - | - |

| DIN 2631 PN 6 (in mm) | ||||||||||||||

| Nominal Pipe Size | Diameter at weld Bevel | Flange Dia | Thk of Flange | Dia of Bolt Circle | Length Through Hub | Dia of Hub | Wall Thk | Radius of Hub | Straight Portion | Dia of R/F | Thk of R/F | No. of | Dia of Bolt Holes | |

| DN | D1 | D | B | K | H1 | D3 | S | R | H2 | D4 | F | holes | D2 | KG |

| 10 | 17.20 | 75 | 12 | 50 | 28 | 26 | 1.8 | 4 | 6 | 35 | 2 | 4 | 11 | 0.34 |

| 15 | 21.30 | 80 | 12 | 55 | 30 | 30 | 2 | 4 | 6 | 40 | 2 | 4 | 11 | 0.40 |

| 20 | 26.90 | 90 | 14 | 65 | 32 | 38 | 2.3 | 4 | 6 | 50 | 2 | 4 | 11 | 0.60 |

| 25 | 33.70 | 100 | 14 | 75 | 35 | 42 | 2.6 | 4 | 6 | 60 | 2 | 4 | 11 | 0.75 |

| 32 | 42.40 | 120 | 14 | 90 | 35 | 55 | 2.6 | 6 | 6 | 70 | 2 | 4 | 14 | 1.06 |

| 40 | 48.30 | 130 | 14 | 100 | 38 | 62 | 2.6 | 6 | 7 | 80 | 3 | 4 | 14 | 1.20 |

| 50 | 60.30 | 140 | 14 | 110 | 38 | 74 | 2.9 | 6 | 8 | 90 | 3 | 4 | 14 | 1.36 |

| 65 | 76.10 | 160 | 14 | 130 | 38 | 88 | 2.9 | 6 | 9 | 110 | 3 | 4 | 14 | 1.69 |

| 80 | 88.90 | 190 | 16 | 150 | 42 | 102 | 3.2 | 8 | 10 | 128 | 3 | 4 | 18 | 2.72 |

| 100 | 114.30 | 210 | 16 | 170 | 45 | 130 | 3.6 | 8 | 10 | 148 | 3 | 4 | 18 | 3.22 |

| 125 | 139.70 | 240 | 18 | 200 | 48 | 155 | 4 | 8 | 10 | 178 | 3 | 8 | 18 | 4.42 |

| 150 | 168 | 265 | 18 | 225 | 48 | 184 | 4.5 | 10 | 12 | 202 | 3 | 8 | 18 | 5.04 |

| 200 | 219.10 | 320 | 20 | 280 | 55 | 236 | 5.9 | 10 | 15 | 258 | 3 | 8 | 18 | 7.95 |

| 250 | 273.00 | 375 | 22 | 335 | 60 | 290 | 6.3 | 12 | 15 | 312 | 3 | 12 | 18 | 10.87 |

| 300 | 323.90 | 440 | 22 | 395 | 62 | 342 | 7.1 | 12 | 15 | 365 | 4 | 12 | 22 | 14.26 |

| 350 | 355.60 | 490 | 22 | 445 | 62 | 385 | 7.1 | 12 | 15 | 415 | 4 | 12 | 22 | 16.78 |

| 400 | 406.60 | 540 | 22 | 495 | 65 | 438 | 7.1 | 12 | 15 | 465 | 4 | 16 | 22 | 19.10 |

| 500 | 508.00 | 645 | 24 | 600 | 68 | 538 | 7.1 | 12 | 15 | 570 | 4 | 20 | 22 | 28.67 |

| 600 | 610.00 | 755 | 24 | 705 | 70 | 640 | 7.1 | 12 | 16 | 670 | 5 | 20 | 26 | 34.80 |

| 700 | 711.00 | 860 | 24 | 810 | 70 | 740 | 7.1 | 12 | 16 | 775 | 5 | 24 | 26 | 40.94 |

| 800 | 813.00 | 975 | 24 | 920 | 70 | 842 | 7.1 | 12 | 16 | 880 | 5 | 24 | 30 | 49.19 |

| 900 | 914.00 | 1075 | 26 | 1020 | 70 | 942 | 7.1 | 12 | 16 | 980 | 5 | 24 | 30 | 58.10 |

| 1000 | 1016.00 | 1175 | 26 | 1120 | 70 | 1045 | 7.1 | 16 | 16 | 1080 | 5 | 28 | 30 | 63.48 |

| 1200 | 1220.00 | 1405 | 28 | 1340 | 90 | 1248 | 8 | 16 | 20 | 1295 | 5 | 32 | 33 | 100.17 |

| 1400 | 1420.00 | 1630 | 32 | 1560 | 90 | 1452 | 8 | 16 | 20 | 1510 | 5 | 36 | 36 | 142.78 |

| 1600 | 1620.00 | 1830 | 34 | 1760 | 90 | 1655 | 9 | 16 | 20 | 1710 | 5 | 40 | 36 | 174.36 |

| 1800 | 1820.00 | 2045 | 36 | 1970 | 100 | 1855 | 10 | 16 | 20 | 1920 | 5 | 44 | 39 | 226.98 |

| 2000 | 2020.00 | 2265 | 38 | 2180 | 110 | 2058 | 11 | 16 | 25 | 2125 | 5 | 48 | 42 | 292.12 |

| 2200 | 2220.00 | 2475 | 42 | 2390 | 115 | 2260 | 12 | 18 | 25 | 2335 | 6 | 52 | 42 | 366.33 |

| 2400 | 2420.00 | 2685 | 44 | 2600 | 125 | 2462 | 13 | 18 | 25 | 2545 | 6 | 56 | 42 | 448.52 |

| 2600 | 2620.00 | 2905 | 46 | 2810 | 130 | 2665 | 14 | 18 | 25 | 2750 | 6 | 60 | 48 | 540.16 |

| 2800 | 2820.00 | 3115 | 48 | 3020 | 135 | 2865 | 15 | 18 | 30 | 2960 | 6 | 64 | 48 | 630.03 |

| 3000 | 3020.00 | 3315 | 50 | 3220 | 140 | 3068 | 16 | 18 | 30 | 3160 | 6 | 68 | 48 | 716.33 |

| 3200 | 3220.00 | 3525 | 54 | 3430 | 150 | 3272 | 16 | 20 | 30 | 3370 | 6 | 72 | 48 | 854.42 |

| 3400 | 3420.00 | 3735 | 46 | 3640 | 160 | 3475 | 18 | 20 | 35 | 3580 | 6 | 76 | 48 | 887.81 |

| 3600 | 3620.00 | 3970 | 60 | 3860 | 165 | 3678 | 18 | 20 | 35 | 3790 | 6 | 80 | 56 | 1202.43 |

| DIN 2632 PN 10 (in mm) | ||||||||||||||

| Nominal Pipe Size | Diameter at weld Bevel | Flange Dia | Thk of Flange | Dia of Bolt Circle | Length Through Hub | Dia of Hub | Wall Thk | Radius of Hub | Straight Portion | Dia of R/F | Thk of R/F | No. of | Dia of Bolt Holes | |

| DN | D1 | D | B | K | H1 | D3 | S | R | H2 | D4 | F | holes | D2 | KG |

| 10 | 17.2 | 90 | 14 | 60 | 35 | 28 | 1.8 | 4 | 6 | 40 | 2 | 4 | 14 | 0.58 |

| 15 | 21.3 | 95 | 14 | 65 | 35 | 32 | 2.0 | 4 | 6 | 45 | 2 | 4 | 14 | 0.65 |

| 20 | 26.9 | 105 | 16 | 75 | 38 | 40 | 2.3 | 4 | 6 | 58 | 2 | 4 | 14 | 0.95 |

| 25 | 33.7 | 115 | 16 | 85 | 38 | 45 | 2.6 | 4 | 6 | 68 | 2 | 4 | 14 | 1.14 |

| 32 | 42.4 | 140 | 16 | 100 | 40 | 55 | 2.6 | 6 | 6 | 78 | 2 | 4 | 18 | 1.65 |

| 40 | 48.3 | 150 | 16 | 110 | 42 | 64 | 2.6 | 6 | 7 | 88 | 3 | 4 | 18 | 1.83 |

| 50 | 60.3 | 165 | 18 | 125 | 45 | 75 | 2.9 | 6 | 8 | 102 | 3 | 4 | 18 | 2.48 |

| 65 | 76.1 | 165 | 18 | 145 | 45 | 90 | 2.9 | 6 | 10 | 122 | 3 | 4 | 18 | 3.03 |

| 80 | 88.9 | 200 | 20 | 160 | 50 | 105 | 3.2 | 6 | 10 | 138 | 3 | 8 | 18 | 3.82 |

| 100 | 114.3 | 220 | 20 | 180 | 52 | 131 | 3.6 | 8 | 12 | 158 | 3 | 8 | 18 | 4.41 |

| 125 | 139.7 | 250 | 22 | 210 | 55 | 156 | 4.0 | 8 | 12 | 188 | 3 | 8 | 18 | 6.07 |

| 150 | 168.3 | 285 | 22 | 240 | 55 | 184 | 4.5 | 10 | 12 | 212 | 3 | 8 | 22 | 7.40 |

| 200 | 219.1 | 340 | 24 | 295 | 62 | 235 | 5.9 | 10 | 16 | 268 | 3 | 8 | 22 | 11.10 |

| 250 | 273.0 | 395 | 26 | 350 | 68 | 292 | 6.3 | 12 | 16 | 320 | 3 | 12 | 22 | 14.92 |

| 300 | 323.9 | 445 | 26 | 400 | 68 | 344 | 7.1 | 12 | 16 | 370 | 4 | 12 | 22 | 17.47 |

| 350 | 355.6 | 505 | 26 | 460 | 66 | 385 | 7.1 | 12 | 16 | 430 | 4 | 16 | 22 | 23.70 |

| 400 | 406.4 | 565 | 26 | 515 | 72 | 440 | 7.1 | 12 | 16 | 482 | 4 | 16 | 26 | 28.72 |

| 450 | 457.2 | 615 | 26 | 565 | 72 | 478 | 7.1 | 12 | 16 | 532 | 4 | 20 | 26 | 30.40 |

| 500 | 508.0 | 670 | 28 | 620 | 75 | 542 | 7.1 | 12 | 16 | 585 | 4 | 20 | 26 | 38.27 |

| 600 | 610.0 | 780 | 28 | 725 | 80 | 642 | 7.1 | 12 | 18 | 685 | 5 | 20 | 30 | 46.56 |

| 700 | 711.0 | 895 | 30 | 840 | 80 | 745 | 8.0 | 12 | 18 | 800 | 5 | 24 | 30 | 62.30 |

| 800 | 813.0 | 1015 | 32 | 950 | 90 | 850 | 8.0 | 12 | 18 | 905 | 5 | 24 | 33 | 83.81 |

| 900 | 914.0 | 1115 | 34 | 1050 | 95 | 950 | 10.0 | 12 | 20 | 1005 | 5 | 28 | 33 | 102.45 |

| 1000 | 1016.0 | 1230 | 34 | 1160 | 95 | 1052 | 10.0 | 16 | 20 | 1110 | 5 | 28 | 36 | 118.53 |

| 1200 | 1220.0 | 1455 | 36 | 1380 | 115 | 1255 | 11.0 | 16 | 25 | 1330 | 5 | 32 | 39 | 178.18 |

| 1400 | 1420.0 | 1675 | 42 | 1590 | 120 | 1460 | 12.0 | 16 | 25 | 1535 | 5 | 36 | 42 | 244.75 |

| 1600 | 1620.0 | 1915 | 46 | 1820 | 130 | 1665 | 14.0 | 16 | 25 | 1760 | 5 | 40 | 48 | 353.74 |

| 1800 | 1820.0 | 2115 | 50 | 2020 | 140 | 1868 | 15.0 | 16 | 30 | 1960 | 5 | 44 | 48 | 436.33 |

| 2000 | 2020.0 | 2325 | 54 | 2230 | 150 | 2072 | 16.0 | 16 | 30 | 2170 | 5 | 46 | 48 | 548.04 |

| 2200 | 2220.0 | 2550 | 58 | 2440 | 160 | 2275 | 18.0 | 18 | 35 | 2370 | 5 | 52 | 56 | 685.10 |

| 2400 | 2420.0 | 2760 | 62 | 2650 | 170 | 2478 | 20.0 | 18 | 35 | 2570 | 5 | 56 | 56 | 640.04 |

| 2600 | 2620.0 | 2860 | 66 | 2850 | 180 | 2690 | 22.0 | 18 | 40 | 2780 | 6 | 60 | 56 | 990.16 |

| 2800 | 2820.0 | 3180 | 70 | 3070 | 190 | 2882 | 22.0 | 18 | 40 | 3000 | 6 | 64 | 56 | 1187.16 |

| 3000 | 3020.0 | 3405 | 75 | 3290 | 200 | 3085 | 24.0 | 18 | 45 | 3210 | 6 | 65 | 62 | 1437.06 |

| DIN 2633 PN16 (in mm) | ||||||||||||||

| Nominal Pipe Size | Diameter at weld Bevel | Flange Dia | Thk of Flange | Dia of Bolt Circle | Length Through Hub | Dia of Hub | Wall Thk | Radius of Hub | Straight Portion | Dia of R/F | Thk of R/F | No. of | Dia of Bolt Holes | |

| DN | D1 | D | B | K | H1 | D3 | S | R | H2 | D4 | F | holes | D2 | KG |

| 10 | 17.2 | 90 | 14 | 60 | 35 | 28 | 1.8 | 4 | 6 | 40 | 2 | 4 | 14 | 0.58 |

| 15 | 21.3 | 95 | 14 | 65 | 35 | 32 | 2.0 | 4 | 6 | 45 | 2 | 4 | 14 | 0.65 |

| 20 | 26.9 | 105 | 16 | 75 | 38 | 40 | 2.3 | 4 | 6 | 58 | 2 | 4 | 14 | 0.95 |

| 25 | 33.7 | 115 | 16 | 85 | 38 | 45 | 2.6 | 4 | 6 | 68 | 2 | 4 | 14 | 1.14 |

| 32 | 42.4 | 140 | 16 | 100 | 40 | 56 | 2.6 | 6 | 6 | 78 | 2 | 4 | 18 | 1.65 |

| 40 | 48.3 | 150 | 16 | 110 | 42 | 64 | 2.6 | 6 | 7 | 88 | 3 | 4 | 18 | 1.83 |

| 50 | 60.3 | 165 | 18 | 125 | 45 | 75 | 2.9 | 6 | 8 | 102 | 3 | 4 | 18 | 2.48 |

| 65 | 76.1 | 185 | 18 | 145 | 45 | 90 | 2.9 | 6 | 10 | 122 | 3 | 4 | 18 | 3.03 |

| 80 | 88.9 | 200 | 20 | 160 | 50 | 105 | 3.2 | 8 | 10 | 138 | 3 | 8 | 18 | 3.82 |

| 100 | 114.3 | 220 | 20 | 180 | 52 | 131 | 3.6 | 8 | 12 | 158 | 3 | 8 | 18 | 4.41 |

| 125 | 139.7 | 250 | 22 | 210 | 55 | 156 | 4.0 | 8 | 12 | 188 | 3 | 8 | 18 | 6.07 |

| 150 | 168.3 | 285 | 22 | 240 | 55 | 184 | 4.5 | 10 | 12 | 212 | 3 | 8 | 22 | 7.40 |

| 175 | 193.7 | 315 | 24 | 270 | 60 | 210 | 5.4 | 10 | 12 | 242 | 3 | 8 | 22 | 9.86 |

| 200 | 219.1 | 340 | 24 | 295 | 62 | 235 | 5.9 | 10 | 16 | 268 | 3 | 12 | 22 | 10.85 |

| 250 | 273.0 | 405 | 26 | 355 | 70 | 292 | 6.3 | 12 | 16 | 320 | 3 | 12 | 26 | 15.87 |

| 300 | 323.9 | 460 | 28 | 410 | 78 | 344 | 7.1 | 12 | 16 | 378 | 4 | 12 | 26 | 21.24 |

| 350 | 355.6 | 520 | 30 | 470 | 82 | 390 | 8.0 | 12 | 16 | 438 | 4 | 16 | 26 | 31.38 |